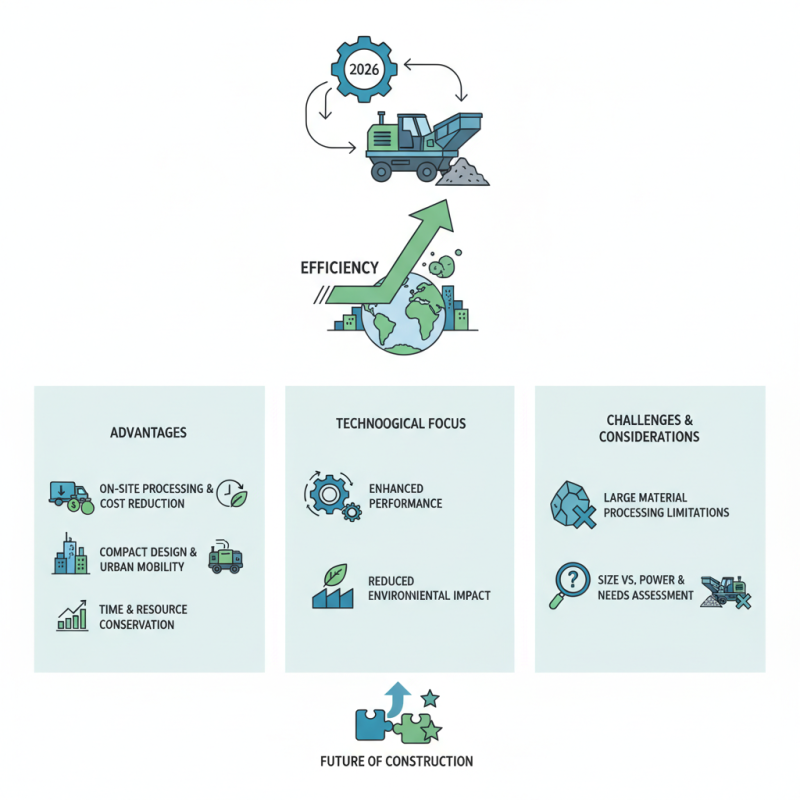

The construction industry is evolving rapidly, incorporating advanced technologies for efficiency. One significant innovation is the Portable Crusher. This equipment enables on-site material processing, minimizing transport costs. With less material moving to and from sites, both time and resources are conserved.

Recent developments in Portable Crusher technology have focused on enhancing performance and reducing environmental impact. Compact designs improve mobility, making these machines ideal for urban projects. However, users must consider the balance between size and power. Performance may be compromised if not properly assessed.

Despite the benefits, there are challenges. Some Portable Crushers may struggle with larger materials. This can lead to inefficiencies that need careful planning. Construction companies should evaluate their specific needs and choose the right model. Continuous improvement in this area is essential for future success. Overall, the innovation in Portable Crushers shows promise but requires thoughtful implementation.

The construction industry is seeing exciting changes in portable crusher designs for 2026. Many companies are focusing on lightweight materials to improve mobility. These new designs often feature compact dimensions, allowing for easier transportation. Reduced weight can potentially lead to increased fuel efficiency, contributing to green initiatives in the construction sector.

Innovations also include enhanced automation features. Some crushers now come with smart technology that allows operators to monitor performance remotely. This results in better decision-making on job sites. However, reliance on technology can be a double-edged sword. If the systems fail, it could lead to project delays and increased costs.

Another trend is the integration of eco-friendly solutions. Many portable crushers now aim to minimize noise and dust emissions. This not only benefits workers but also the surrounding environment. Yet, some designs might sacrifice power for eco-friendliness. Finding the right balance is essential as the industry moves forward. These innovations are promising but need continuous refinement for optimal performance.

The construction industry constantly seeks efficient methods to enhance productivity. Innovations in portable crushing technology are driving this transformation. These advancements streamline material processing, reducing operation time on job sites. With lightweight designs, modern portable crushers allow easy relocation. This capability enhances project flexibility, adapting to various environments.

Recent developments include improved energy efficiency. Many new models use less fuel yet achieve higher output. These changes can lead to significant cost savings over time. However, challenges remain. Despite advancements, some models struggle with durability under heavy use. Regular maintenance is essential to ensure longevity.

Safety remains a crucial concern. Some portable crushers may not meet evolving safety standards. Operators must be aware of these risks. Training is essential for effective and safe machine use. In an ever-changing industry, staying informed is vital. As the construction landscape shifts, so must the technology that supports it.

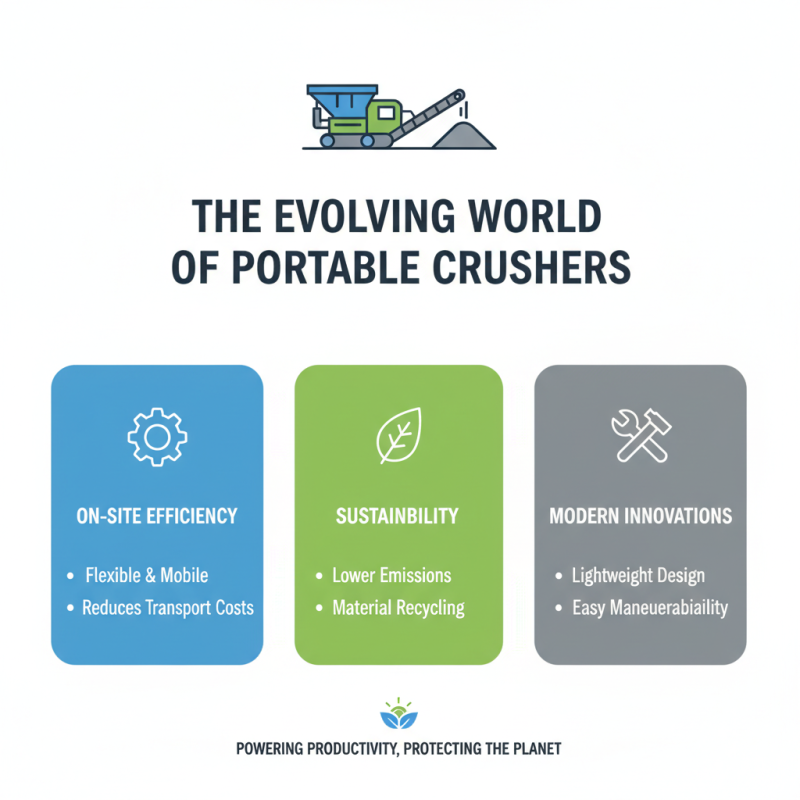

In the ever-evolving construction industry, portable crushers play a vital role. These machines are designed for on-site use, offering flexibility and efficiency. Modern innovations focus on enhancing productivity while minimizing the environmental impact. Key features of these advanced crushers include lightweight designs and easy maneuverability. This allows operators to easily transport them between job sites.

One remarkable feature is the automated control system. It simplifies operations, reducing the need for manual intervention. Also, noise reduction technologies make them suitable for urban projects. Operators can work without disturbing the surrounding area. Additionally, some models come equipped with energy-efficient motors, contributing to lower operational costs.

Tips: Always ensure regular maintenance. It prolongs the life of the equipment and prevents unexpected downtime. Consider the power source; opting for electric models can reduce emissions. Remember, not all innovations may fit every project. Evaluate specific needs before investing in new equipment.

The advancement of portable crushers significantly impacts environmental sustainability in construction. These machines are designed to reduce emissions and utilize green technologies. Many new models prioritize energy efficiency, using less fuel while maintaining high output. This shift can lower a construction site’s carbon footprint, which is crucial for eco-friendly practices.

However, challenges remain. Not all innovations are widely adopted, leading to varied industry practices. Some portable crushers still rely on outdated technologies, increasing potential pollution. The market’s growth needs regulations to ensure that new innovations align with environmental standards. Site operators must reflect on their equipment choices, balancing efficiency and sustainability.

The push for greener solutions is vital, yet it’s inconsistent. Some companies invest in research, while others lag behind. This divide highlights areas for improvement within the industry. Continued emphasis on environmental impact will shape the future of portable crushers, but only if companies commit to meaningful change.

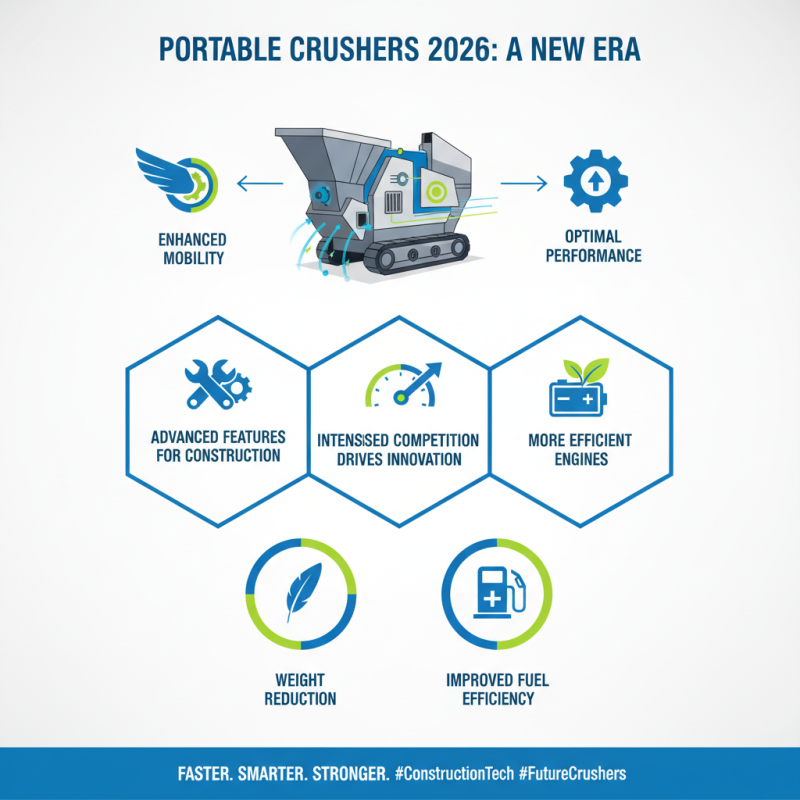

In 2026, the landscape of portable crushers has transformed significantly. Many brands now offer advanced features for construction solutions. The competition has intensified, pushing innovations to the forefront. Key improvements include weight reduction and more efficient engines. These features enhance mobility and overall performance on job sites.

Tips: When choosing a portable crusher, consider your specific project needs. Assess the size and weight. Also, look for energy-efficient models. They can save costs in the long run. Moreover, user feedback can provide insight into reliability and ease of use.

Despite advancements, challenges remain. Some models may lack the durability required for harsh environments. Not all innovations translate to practical benefits. It’s essential to weigh features against real-world performance. Balancing efficiency with reliability can be tricky. Always do thorough research before making a decision.