In the rapidly evolving construction industry, the demand for efficient machinery has never been higher. The "Limestone Crusher Machine" stands out for its essential role in processing limestone, a key material in various applications. According to a recent report by the National Stone, Sand & Gravel Association, the U.S. limestone production reached over 60 million tons in 2022 alone, highlighting its significance in construction projects.

Expert Alan R. McKenzie, a noted authority in crushing technology, emphasizes, “Investing in a limestone crusher machine can drastically enhance production efficiency.” Companies are constantly seeking ways to optimize operations, reduce costs, and improve results. Integrating a limestone crusher machine can lead to streamlined processes and high-quality outputs. Yet, careful evaluation is necessary.

While these machines are beneficial, they require proper maintenance and an upfront investment. It's crucial for businesses to reflect on their specific needs and capabilities. Misjudgments in choosing the right equipment can lead to inefficiencies. Balancing benefits with practicality is a challenge that every business must face.

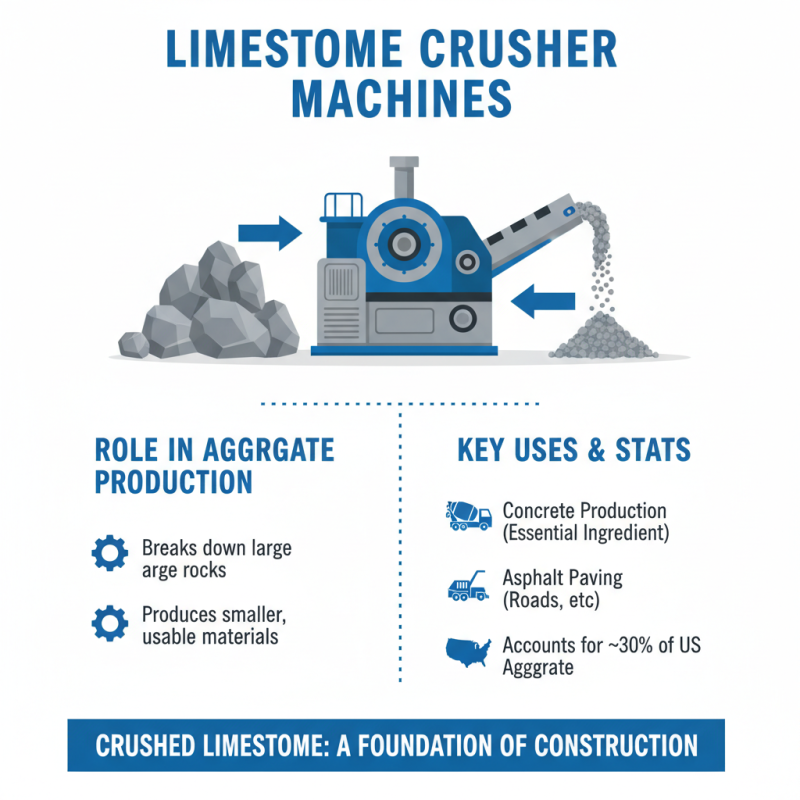

Limestone crusher machines play a crucial role in aggregate production. These machines break down large limestone rocks into smaller, usable materials. According to industry reports, crushed limestone is a key ingredient in concrete and asphalt. It accounts for nearly 30% of the total aggregate production in the U.S.

Using limestone crushers can enhance efficiency in operations. It reduces manual labor, which can lower operational costs. Data shows that companies using automated crushing equipment increase productivity by up to 40%. This is significant for businesses aiming to boost output while maintaining quality. Workers can focus on other essential tasks, allowing for better resource management.

However, the transition to limestone crushers is not always smooth. Some operators struggle with maintenance and operational training. This can lead to unexpected downtimes and challenges in integrating new technologies. Regular training and support are crucial for realizing the full benefits. Additionally, the environmental impacts of increased machinery use must be continually assessed. Addressing these challenges can lead to sustained growth in aggregate production.

In the world of crushing processes, efficiency is key. Limestone crusher machines play a crucial role in improving production rates. A recent industry report indicates that using advanced limestone crushers can increase material processing efficiency by up to 30%. This means businesses can crush more limestone in less time, significantly boosting productivity.

Moreover, the operational costs are reduced. With higher efficiency comes lower energy consumption. For instance, using a limestone crusher can lead to a 20% reduction in energy use, according to a study from a leading mining association. However, companies must be cautious. Not all limestone crushers are built equally; choosing the right machine is essential. Some models are noisy and may require frequent maintenance, which can negate efficiency gains.

Additionally, the quality of crushed limestone is vital. If the crusher does not produce consistent sizing, it affects downstream processes. A report found that inconsistent output can lead to a 15% decrease in product quality. This can spring back on businesses in the form of additional processing steps. Therefore, while limestone crushers offer considerable benefits, they require thoughtful consideration and proper maintenance to truly deliver their potential.

Limestone crushers play a crucial role in material processing. They help businesses reduce costs significantly. For those involved in construction or mining, these machines are a game changer. The efficiency of limestone crushers means less energy use and lower operational costs. They can handle large volumes, which translates to better productivity.

Using limestone crushers can also minimize waste. The crushed material is often reused, reducing the need for additional resources. This not only lowers expenses but is also an eco-friendly option. However, choosing the right type of crusher is essential. A machine that is too large can lead to increased costs without proportional benefits.

Maintenance is a crucial factor when discussing cost-effectiveness. Regular upkeep is needed to keep the machines running efficiently. Neglect can lead to breakdowns and costly repairs. Balancing performance and maintenance can be challenging. Businesses need to weigh initial savings against potential long-term costs. Ultimately, understanding these dynamics is vital for making informed investments in limestone processing.

Limestone crushing operations play a significant role in promoting environmental sustainability. The process reduces energy consumption compared to traditional methods. According to a report by the National Stone, Sand & Gravel Association, the use of modern limestone crushers can lower energy usage by as much as 20%. This means less fossil fuel consumption, which directly impacts carbon emissions.

Moreover, limestone crushers contribute to resource efficiency. By utilizing high-quality crushed limestone, businesses can produce eco-friendly products. The same association states that up to 90% of the materials used in infrastructure projects can be sourced from crushed limestone. This local sourcing minimizes transportation emissions, which adds to a lower carbon footprint.

However, limestone crushing is not without its challenges. Dust generation during the crushing process can lead to air quality issues if not properly managed. Additionally, land use for limestone quarries can impact local ecosystems. It is crucial for industries to adopt best practices in dust control and land reclamation. The balance between economic benefits and environmental impact requires ongoing reflection and improvement.

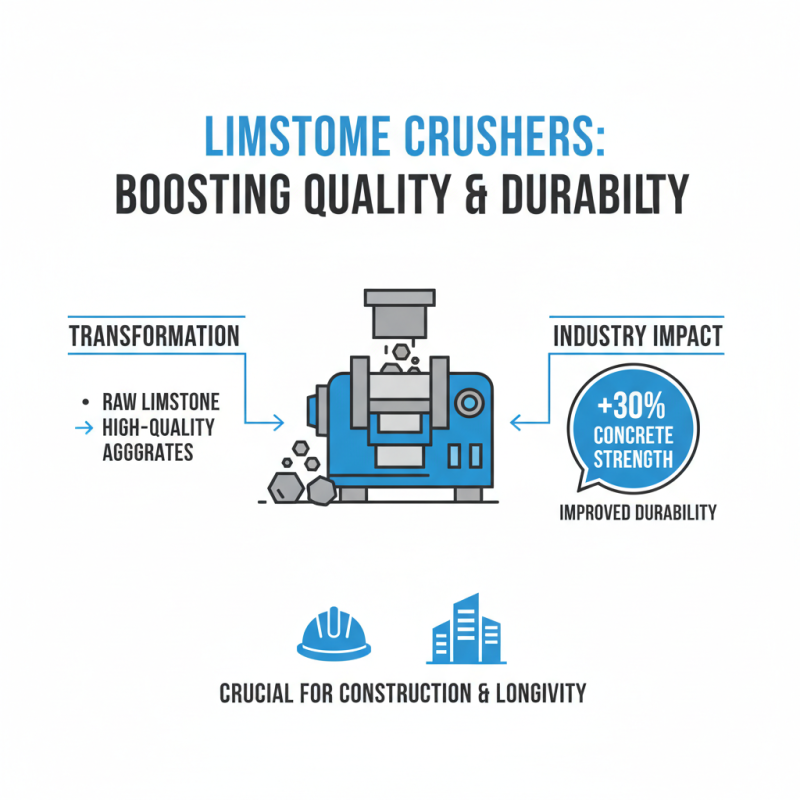

Limestone crushers play a vital role in enhancing product quality and durability in various industries. They transform raw limestone into high-quality aggregates. According to industry reports, the use of limestone aggregates can improve concrete strength by nearly 30%. This enhancement is crucial for construction projects, where durability is key to longevity.

The crushing process ensures uniform particle size, which is essential for consistent material properties. Research shows that uniformly crushed limestone can lead to a reduction in the porosity of concrete. This results in lower water absorption, thereby increasing the structural integrity of constructed buildings. However, improper handling of the limestone crusher can lead to delays and increased operational costs.

Moreover, the wear and tear of machinery need constant attention. Regular maintenance is essential to ensure the limestone crusher operates efficiently. Neglecting this aspect can result in lower quality output and increased downtime. Proper training of operators is also necessary, as inexperienced users may not maximize the machine's potential. Thus, while limestone crushers offer significant benefits, there are challenges that businesses must address to fully leverage their advantages.