In the ever-evolving world of mining, efficiency is key. Among the various tools available, the Granite Stone Crusher stands out. Dr. John Smith, a notable expert in mining technology, states, “Choosing the right granite stone crusher can make or break a mining operation.” His insight underscores the importance of selecting quality machinery for effective results.

Granite is incredibly hard and durable, making it a favored material in construction and landscaping. However, processing this material requires specialized equipment. The Granite Stone Crusher transforms raw granite into manageable sizes for various uses. Understanding the nuances of these machines can greatly impact production efficiency. Every mining operation faces unique challenges. The wrong equipment could lead to costly downtime and wasted resources.

Today, numerous options exist, from jaw crushers to cone crushers. Each type serves a specific purpose in the crushing process. Yet, not all crushers are created equal. An effective granite stone crusher must balance power, efficiency, and reliability. Many equipment choices can be overwhelming. Identifying the right one will require careful consideration and reflection on current operations.

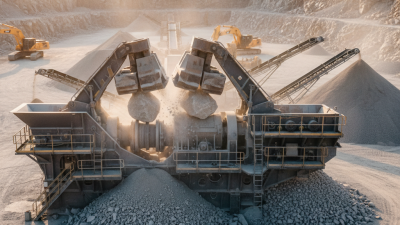

Granite stone crushers play a vital role in mining operations. These machines are crucial for breaking down large granite formations into manageable sizes. In the mining industry, efficiency often determines profitability. Properly crushed granite allows for easier transport and processing, leading to higher yields.

Granite crushers come in various types and sizes. Each type serves different needs, but selecting the right model can be challenging. Some machines may lack the durability needed for rough environments. Others might not meet productivity expectations. An inefficient crusher can lead to costly downtimes and wasted resources.

Operators must consider specific factors like output capacity and maintenance requirements. Choosing the wrong crusher can affect the entire mining operation. Furthermore, not all equipment is user-friendly. This complexity often means additional training for staff. It’s essential to reflect on past choices and seek continuous improvement in equipment selection and management practices.

This chart displays the efficiency of the top 10 granite stone crushers used in mining operations. Each crusher's performance is measured in tons per hour, highlighting their capability to enhance mining productivity.

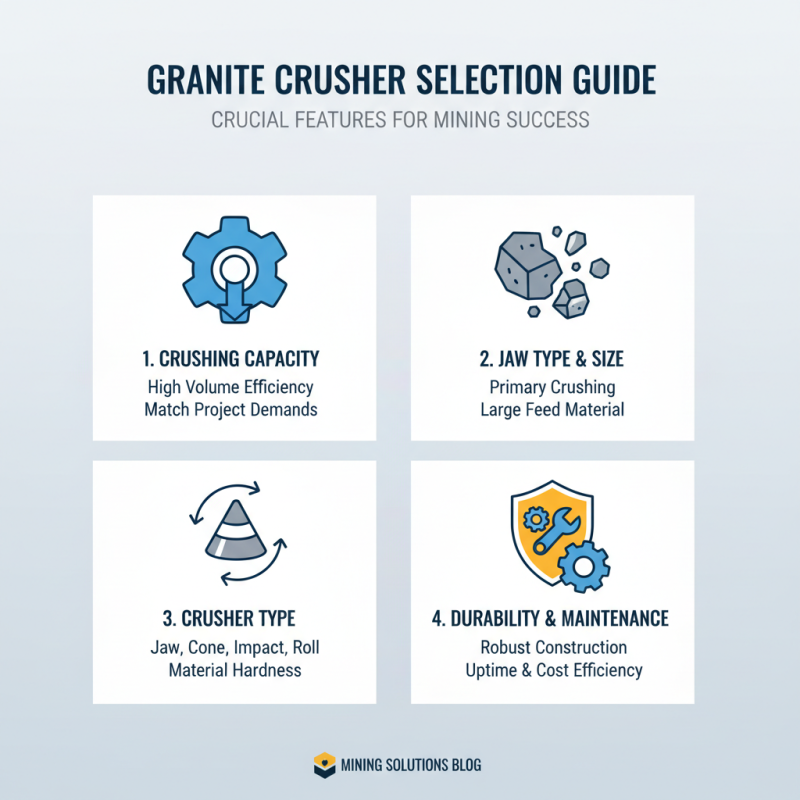

Selecting the right granite stone crusher is crucial for successful mining operations. Several key features should be considered. First, the crushing capacity is vital. You need machines that can handle large volumes efficiently. A lower capacity may lead to operational delays. Make sure to assess the throughput rate to ensure it matches your project demands.

Another important factor is the durability of the machinery. Granite is tough, so the crusher must be robust. Look for features that minimize wear and tear. Components made from high-quality materials can prolong the machine's life. Additionally, consider the maintenance requirements. Some machines may require frequent servicing, leading to increased downtime.

Finally, assess the portability of the crusher. In mining, the ability to move equipment is essential. A portable crusher can adapt to different site conditions. This flexibility can improve overall efficiency. However, remember that a lightweight design may compromise some strength. Finding the right balance is key.

Choosing the right granite stone crusher is crucial for mining efficiency. In the industry, effective crushing can increase production rates by over 30%. The right equipment reduces downtime and improves material quality. Recent reports indicate that advanced crushers are more energy-efficient, consuming up to 20% less power. This is significant in cost-saving for mining operations.

In the competitive market of granite stone crushers, features can make a difference. Look for machines with adjustable settings to handle various sizes of granite. Crusher efficiency often hinges on the material’s hardness. Heavier-duty models handle tougher materials better, enhancing overall performance.

**Tips:** Regular maintenance is key. Schedule inspections to avoid unexpected breakdowns. Moreover, training operators on best practices ensures optimal performance. Investing in the latest technology pays off in the long run. Reflecting on operational challenges can lead to better decisions for equipment upgrades.

When selecting granite stone crushers, performance and durability are crucial. Many machines promise high efficiency, but the results can vary. A crusher's jaw design can significantly impact its output. Some models have a wider gap, known to handle larger stones but may sacrifice crushing efficiency. Others focus on compactness, ensuring they provide consistent results with smaller materials.

Durability often comes down to materials used in construction. Crushers made from high-quality steel tend to last longer under tough conditions. However, some operators report issues with wear and tear, particularly in high-volume operations. Regular maintenance is essential, yet many overlook it, leading to unexpected breakdowns. Performance can degrade over time if manufacturers' guidelines aren’t followed.

Many factors influence how well a granite crusher performs in an actual mining environment. The type of granite being mined plays a crucial role. Harder granite requires more robust machinery, while softer varieties are easier on the equipment. Operators often find themselves evaluating their machines’ efficiency. They discover that they may need to adjust settings, or even choose different models, to keep up with varying demands. This highlights the importance of flexibility in design.

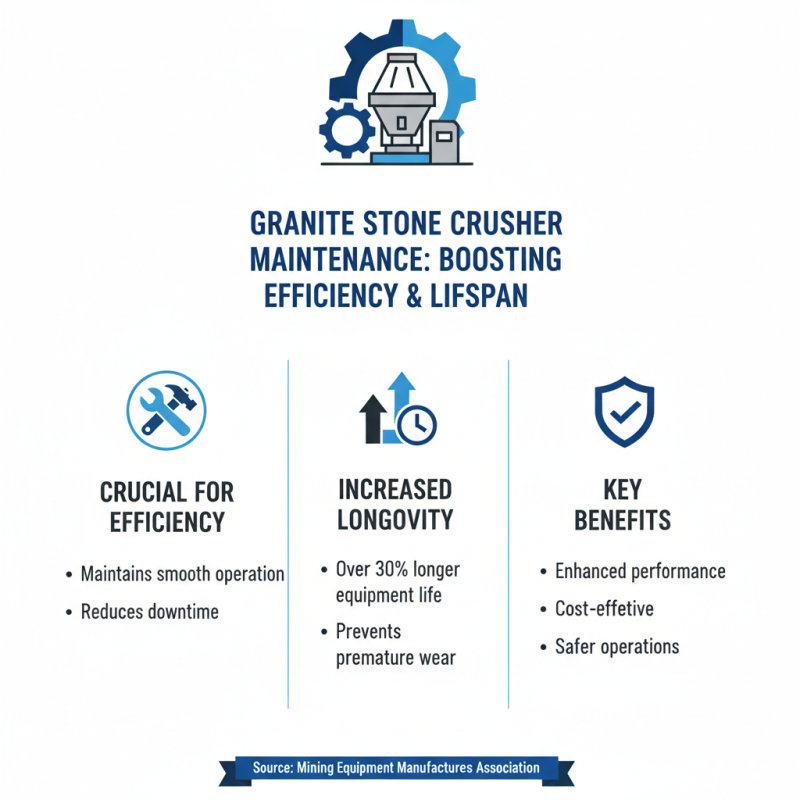

Maintaining granite stone crushers is crucial for efficient mining operations. Regular upkeep can significantly enhance the lifespan and performance of these machines. A report by the Mining Equipment Manufacturers Association indicates that proper maintenance can increase equipment longevity by over 30%.

One essential tip is to conduct daily inspections. Check for any signs of wear and tear, especially on the crushing jaws. Replace worn parts promptly. Ensure that bolts and connections are secure. Tightening loose components can prevent further damage.

Another important practice is to keep the machinery clean. Dust and debris can accumulate, affecting performance. According to industry statistics, uncleaned equipment can lose up to 15% of its efficiency. Regular cleansing not only enhances performance but also helps in spotting potential issues early. Invest in good quality lubricants and make a habit of greasing moving parts. Remember, a small investment in maintenance can save large costs in the long run.