In the ever-evolving world of mining operations, the efficiency and effectiveness of mineral extraction are paramount. One of the key components that influences this process is the choice of equipment, particularly the mineral crusher. Mineral crushers play a crucial role in reducing ore to a manageable size, allowing for easier processing and extraction of valuable materials. As the demand for minerals continues to rise, the importance of selecting the right type of mineral crusher becomes increasingly significant for mining companies aiming to enhance productivity while minimizing operational costs.

In this exploration of the top mineral crushers, we delve into the technological advancements and design innovations that have shaped modern mining practices. Each type of mineral crusher offers unique benefits tailored to specific mining needs and material characteristics. Understanding these variations not only aids in optimizing mining output but also ensures that operations are conducted sustainably and efficiently. By examining the best mineral crushers available, mining operations can be better equipped to meet the challenges of today’s demanding environment, ultimately leading to improved resource management and economic performance.

Mineral crushers play a crucial role in mining operations, serving as the backbone for efficient material processing. These machines are designed to break down rocks and minerals into smaller, manageable sizes, facilitating easier transportation and processing in mineral extraction workflows. By employing various crushing techniques, such as impact, compression, and shear, mineral crushers help optimize the recovery of valuable materials while minimizing waste.

When selecting a mineral crusher, it's essential to consider the type of materials being processed and the desired output size. The right crusher can significantly impact production rates and operational efficiency. For instance, jaw crushers are commonly used for primary crushing due to their ability to handle large feed sizes, while cone crushers are ideal for secondary and tertiary applications that require more precise size reduction.

Tips: Always conduct a thorough analysis of your materials before making a selection. Understanding the hardness, abrasiveness, and moisture content of the minerals will help you choose the optimal crusher. Regular maintenance also ensures longevity and efficient performance, so establish a routine check-up process for your equipment to keep it in top condition. Additionally, train your operators on the best practices for using and maintaining the crushers to maximize productivity in your mining operations.

When selecting the best mineral crushers for efficient mining operations, it's essential to consider several key features that can impact productivity, cost, and overall performance. One of the foremost factors is the type of material being processed. Different minerals have varying hardness levels which will require specific crusher designs to effectively break down the material without excessive wear. For instance, crushers designed for softer minerals may not withstand the intense conditions presented by harder ores.

Another important feature to evaluate is the crusher's capacity and throughput. A crusher that can handle a higher volume will significantly enhance operational efficiency, particularly in large-scale mining operations. It’s crucial to match the crusher's capabilities with your mining needs, ensuring that you can process large quantities of material without bottlenecks that could lead to increased operational costs.

**Tips:** When choosing a mineral crusher, also consider the ease of maintenance and access to replacement parts. Operational downtime can be costly, so opting for models that are known for their reliability and ease of service will pay off in the long run. Additionally, assessing the energy efficiency of the crusher can lead to significant cost savings, as efficient machinery consumes less power and reduces the overall carbon footprint of your operations.

When it comes to enhancing efficiency in mining operations, selecting the right mineral crusher can significantly impact productivity and cost-effectiveness. The top mineral crushers are designed to handle a variety of materials, ensuring that the crushing process is not only swift but also energy-efficient. By choosing crushers that offer advanced technology, durable construction, and optimal performance, mining companies can improve their operational efficiency and reduce downtime.

Tips for selecting the right mineral crusher include assessing your material's hardness and moisture content, as these factors play a crucial role in determining the most suitable type of crusher. Additionally, consider the crusher's capacity and adjustability—this can help accommodate fluctuating operational demands. Regular maintenance and monitoring of the crushing equipment are also essential for maximizing efficiency and preventing unexpected breakdowns.

Furthermore, investing in automated systems and smart technology can enhance the overall efficiency of mineral crushers. These innovations often provide real-time data analytics and diagnostics, allowing operators to make informed decisions quickly. This proactive approach not only boosts productivity but also leads to significant cost savings over time, making it a critical aspect of any successful mining operation.

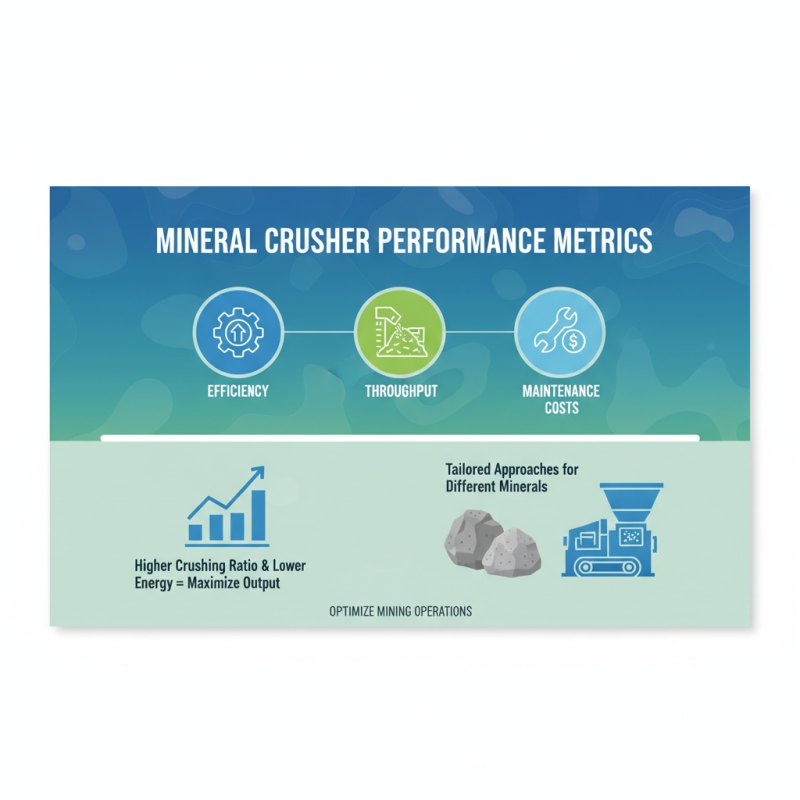

When assessing the performance metrics of mineral crushers, several critical factors come into play that can significantly influence mining operations. Efficiency, throughput, and maintenance costs are vital metrics for evaluating crusher effectiveness. High-efficiency crushers often exhibit superior crushing ratios and reduced energy consumption, allowing operations to maximize output while minimizing operational costs. It’s also crucial to consider the type of minerals being processed, as different materials often require tailored crushing approaches, indicating that a one-size-fits-all solution may not be optimal.

In addition to performance efficiency, the durability and reliability of the equipment are paramount for sustained mining operations. A mineral crusher's longevity can be measured by its capacity to withstand wear and tear, especially when processing hard rock materials. Maintenance intervals and ease of servicing also play a role in operational uptime, where a crusher that is easier to maintain can significantly reduce downtime and associated costs. Ultimately, by comparing these performance metrics, mining operations can make informed decisions on the best mineral crushers to invest in, ensuring they meet both production goals and budgetary constraints.

Proper maintenance of mineral crushers is essential to ensure optimal performance and longevity in mining operations. According to a report by the U.S. Geological Survey, more than 3.1 billion tons of raw minerals were produced in the U.S. alone in 2022, highlighting the importance of efficient machinery. Regular inspection and timely maintenance can significantly reduce operating costs and minimize downtime. For instance, routine checks of wear parts can prevent catastrophic failures, extending the life of your equipment by as much as 30%.

Moreover, keeping crushers clean and free of debris is crucial for maintaining efficiency. Dust and material buildup can lead to overheating and inaccurate readings in monitoring systems, which could result in improper functioning. A study published in the International Journal of Mining Science and Technology indicates that implementing a preventive maintenance schedule can enhance equipment reliability by 25%. Regular lubrication, proper alignment, and vibration analysis are key practices that contribute to reducing wear and tear and maintaining high crushing performance. By prioritizing these maintenance tips, mining operations can achieve more efficient output while reducing the likelihood of unexpected repairs.

| Crusher Type | Crushing Capacity (tons/hour) | Power Consumption (kW) | Max Feed Size (mm) | Maintenance Frequency (months) | Efficiency (%) |

|---|---|---|---|---|---|

| Jaw Crusher | 150 | 110 | 500 | 6 | 90 |

| Cone Crusher | 200 | 160 | 300 | 5 | 92 |

| Impact Crusher | 120 | 100 | 400 | 4 | 88 |

| Gyratory Crusher | 250 | 220 | 600 | 8 | 93 |

| Roll Crusher | 100 | 85 | 200 | 3 | 85 |

| Hammer Mill | 80 | 75 | 150 | 2 | 87 |

| Vertical Shaft Impactor | 90 | 95 | 350 | 6 | 89 |

| Mobile Crusher | 160 | 130 | 450 | 4 | 91 |

| Stone Crusher | 140 | 120 | 350 | 3 | 88 |

| Blow Bar Crusher | 110 | 105 | 300 | 5 | 90 |