When it comes to the construction and mining industries, selecting the right equipment is crucial for optimizing productivity and ensuring efficient operations. One of the most significant pieces of machinery in these fields is the Hard Stone Crusher, which plays a pivotal role in the processing of hard materials such as granite, basalt, and limestone. The choice of a Hard Stone Crusher can profoundly impact not only the quality of the crushed material but also the overall performance and reliability of your operations. Therefore, understanding the key factors that influence the selection process is essential for making an informed decision.

In this guide, we will explore various elements that should be considered when choosing the best Hard Stone Crusher to meet your specific needs. From assessing the size and hardness of the materials to evaluating operational efficiency and maintenance requirements, this comprehensive overview will help you navigate the myriad options available in the market. We will also delve into aspects such as capacity, power consumption, and the latest technologies that enhance the performance of Hard Stone Crushers, ensuring that you find a solution that aligns with your project goals and operational demands.

When selecting a hard stone crusher, it's essential to first assess your crushing capacity needs. This involves understanding both the quantity and type of material you'll be processing. Factors such as the hardness of the stone, feed size, and desired output size play a critical role in determining the appropriate crusher. Conducting a thorough analysis of your specific requirements will help you identify the right specifications needed for optimal performance.

Another vital aspect of assessing your needs is evaluating the operational environment where the crusher will be deployed. Considerations such as site accessibility, available power sources, and the potential for expanding production in the future can influence your choice. Additionally, understanding the maintenance requirements and the technical support available for different models can significantly impact your long-term satisfaction and efficiency. By taking a comprehensive approach to evaluating your needs, you can make a more informed decision that aligns with your operational goals.

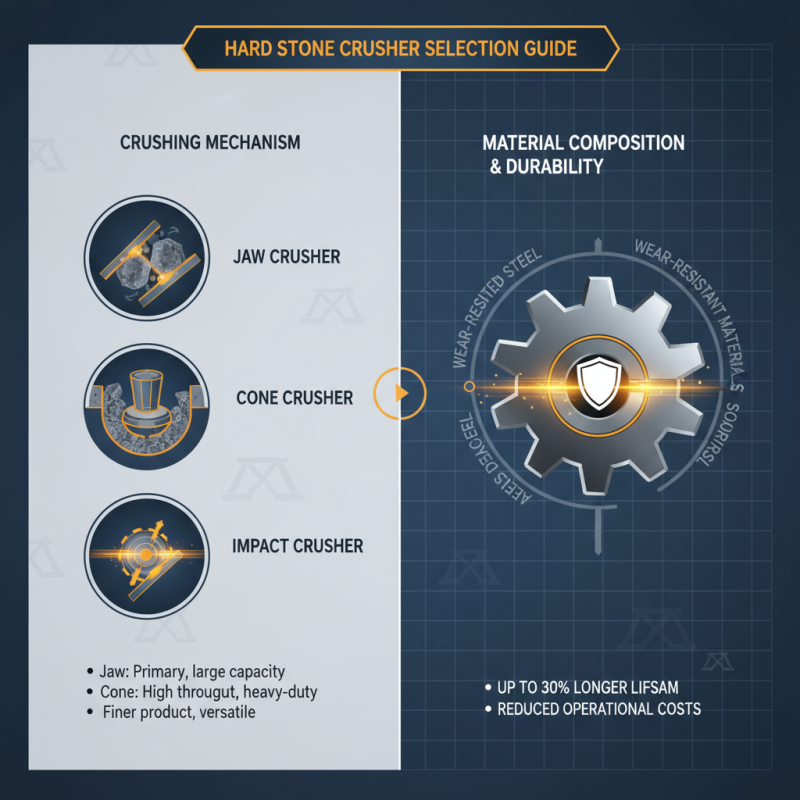

When it comes to selecting the best hard stone crusher for your construction or mining needs, understanding the different types available in the market is crucial. Hard stone crushers can generally be categorized into several types, including jaw crushers, cone crushers, impact crushers, and quarry crushers. Each type of crusher serves a specific purpose and comes with its own unique advantages. For instance, jaw crushers are renowned for their high efficiency and ability to crush tough stones, making them ideal for primary crushing applications.

On the other hand, cone crushers are often favored for their ability to produce finely crushed stone, making them suitable for secondary and tertiary crushing processes. They are designed to handle a wide variety of rock types and sizes, providing versatility in different projects. Impact crushers, known for their high-speed operation, excel in breaking down softer stones and concrete, offering a quick solution for construction debris. Understanding these types and their functionalities will enable you to make an informed decision that aligns with your specific needs, ensuring optimal performance and efficiency in your operations.

| Type of Crusher | Capacity (tons/hour) | Power (kW) | Max Feed Size (mm) | Cost Range (USD) |

|---|---|---|---|---|

| Jaw Crusher | 50-200 | 15-200 | 1000 | 10,000 - 50,000 |

| Cone Crusher | 20-300 | 30-400 | 1500 | 25,000 - 100,000 |

| Impact Crusher | 30-250 | 20-300 | 800 | 15,000 - 70,000 |

| Hammer Crusher | 10-100 | 15-250 | 500 | 5,000 - 25,000 |

| Vertical Shaft Impact Crusher | 50-150 | 22-200 | 500 | 20,000 - 90,000 |

When selecting the best hard stone crusher for your needs, several key features significantly impact both performance and durability. One of the primary considerations is the material composition and design. According to a report by the International Journal of Mining Science and Technology, high-quality crushers made from alloyed steel or wear-resistant materials can extend the lifespan of the machine by up to 30%, reducing operational costs over time. Additionally, examining the crushing mechanism—whether it employs a jaw, cone, or impact design—can influence efficiency. A study indicated that cone crushers typically provide higher throughput rates, making them ideal for heavy-duty applications where performance is critical.

Another crucial feature is the maintenance requirements of the crusher. A comprehensive analysis from Mining Equipment Review found that machines designed for easy access to parts and with automated lubrication systems can reduce downtime by approximately 25%. This operational efficiency not only enhances productivity but also factors into long-term maintenance costs. Furthermore, energy consumption is an increasingly important metric; modern crushers with energy-saving technologies can decrease operational expenses. As the industry trends towards sustainability, selecting a hard stone crusher that prioritizes energy efficiency aligns with both economic and environmental goals. Thus, considering these features ensures optimal performance and longevity in your crushing operations.

When choosing a hard stone crusher, analyzing the cost-effectiveness and return on investment (ROI) is crucial for making an informed decision. According to a recent industry report by Research and Markets, the global stone crushing equipment market is projected to grow from approximately $4.27 billion in 2020 to around $5.61 billion by 2025, highlighting the increasing demand for efficient crushing solutions. This growth emphasizes the importance of selecting the right equipment that balances initial purchase costs with long-term operational efficiency.

Cost-effectiveness can be measured by evaluating not only the purchase price of the crusher but also the ongoing maintenance costs, energy consumption, and the productivity it brings to the operation. A 2021 study published by the Journal of Cleaner Production found that more energy-efficient models of crushers could reduce operational costs by up to 30% over their lifespan. Therefore, investing in a machine that excels in fuel efficiency and throughput can significantly enhance ROI. Furthermore, understanding the average lifespan of different crusher types, which typically ranges from 10 to 15 years, can inform buyers on the long-term benefits of selecting a durable and reliable unit, ensuring they maximize their investment in the competitive stone crushing market.

When selecting the best hard stone crusher, one critical aspect often overlooked is the importance of manufacturer support and maintenance services. A study by the International Journal of Mineral Processing indicates that up to 30% of operational downtime in mining equipment is attributable to inadequate maintenance. This statistic highlights the necessity for manufacturers to provide comprehensive maintenance solutions, ensuring that equipment remains efficient and longevity is maximized.

Moreover, a report from the Quarrying Association points to the fact that 47% of quarry operators prioritize post-sale support as a key factor in their purchasing decisions. This underscores the value of choosing a manufacturer that not only delivers durable equipment but also equips its clients with ongoing support – including training, readily available spare parts, and responsive customer service. Such support can drastically reduce unexpected repair costs and extend the equipment's operational life, which is especially crucial in the competitive landscape of hard stone processing.

Moreover, a report from the Quarrying Association points to the fact that 47% of quarry operators prioritize post-sale support as a key factor in their purchasing decisions. This underscores the value of choosing a manufacturer that not only delivers durable equipment but also equips its clients with ongoing support – including training, readily available spare parts, and responsive customer service. Such support can drastically reduce unexpected repair costs and extend the equipment's operational life, which is especially crucial in the competitive landscape of hard stone processing.

In the long run, investing in a hard stone crusher backed by solid manufacturer support can lead to significant cost savings and enhanced productivity. According to the Construction Equipment Association, companies that engage with manufacturers offering robust support and maintenance services report an average 20% increase in operational efficiency. By considering these factors during the selection process, operators can ensure they are choosing a solution that will meet their needs both now and in the future.