Choosing the right Bentonite Crusher can significantly impact your production efficiency. This decision often feels overwhelming. There are many factors to consider. The right crusher should meet your specific needs and budget.

When selecting a Bentonite Crusher, think about the material's properties. Different crushers suit various tasks. Focus on capacity, size reduction ratio, and maintenance needs. These details can shape your operations. A poorly matched crusher may lead to inefficiency and increased costs.

Consider your intended use as well. Some crushers work better for fine grinding. Others excel in coarse materials. Reflect on your long-term goals. Does the machine adapt to new demands? Making the right choice is crucial for future growth and performance.

Bentonite is a versatile clay that has numerous applications. It is formed from volcanic ash and contains a high percentage of montmorillonite. This natural material is widely used in industries such as construction, agriculture, and environmental protection.

In construction, bentonite is used as a sealing agent. It helps to prevent water seepage in basements and landfills. In agriculture, it can improve soil quality. Farmers use bentonite to enhance water retention and nutrient absorption. Its application also extends to drilling fluids in the oil and gas industry. Here, it helps lubricate and cool drill bits.

Understanding these uses is crucial when selecting a bentonite crusher. Consider the material’s hardness and moisture content. These factors can affect the crushing process. A crusher that works well for one application may not be suitable for another. Assess your specific needs carefully. You might find that trial and error is a part of the decision-making process. Sometimes, optimal choices are only revealed through experimentation.

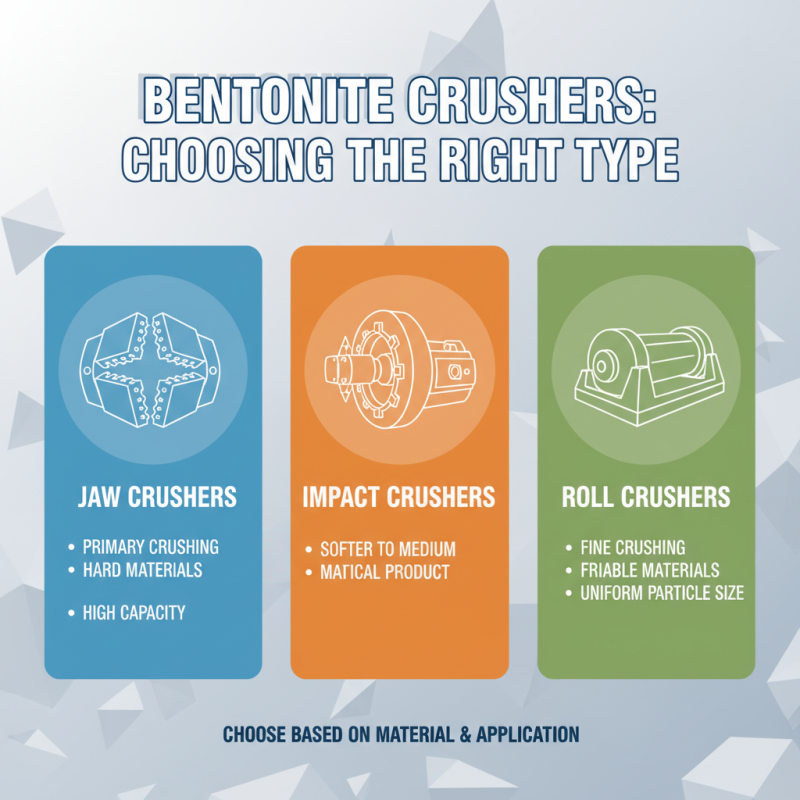

When choosing a bentonite crusher, it’s essential to understand the different types available. Common options include jaw crushers, impact crushers, and roll crushers. Each type has unique features and capabilities tailored to specific processing needs. For instance, jaw crushers are excellent for primary crushing, while impact crushers can handle softer materials efficiently.

Experts suggest that around 40% of efficiency loss often comes from using the wrong type of crusher. It's critical to assess the moisture content and particle size of bentonite. High moisture content can lead to clumping and posing challenges in crushing. According to industry reports, a well-chosen crusher can achieve up to 95% efficiency in specific applications.

For optimal selection, consider the material's characteristics. Does it have impurities? Is the particle size too large? Addressing these questions is vital. Always test the crushed end product. It can reveal whether your crusher choice was appropriate.

Tips: Match the crusher type with your specific bentonite application. Regularly maintain your equipment to avoid performance issues. Be ready to reassess your choice if your production processes change.

Choosing the right bentonite crusher can be challenging.

There are several key factors to consider. First, think about the size of your operation. Small projects may not

need a large machine. Larger operations often require more robust equipment. Assess your material's characteristics.

Is the bentonite dry or wet? This influences the type of crusher

you will need.

Next, consider the desired output size. Different crushers provide various output sizes. Know the specifications

needed for your project. It’s also vital to think about maintenance. Some crushers require more frequent upkeep than others.

This can affect your operational costs in the long run.

Lastly, don’t forget about energy efficiency. A machine

that consumes less power can save money. Sometimes, the cheapest option may not be the most efficient.

Investing in quality might pay off in time. Reflect on your long-term needs before making a decision.

When selecting a bentonite crusher, performance and efficiency are critical factors. Different crushers have varying capabilities. Some models excel in crushing efficiency, while others may have slower rates but better durability. This choice can impact your productivity and operational costs.

Tips: Consider the size of your bentonite material. Larger chunks require more robust machines. Think about the final product too. A finer output needs a different crushing approach.

Another point to reflect on is the energy consumption of the crushers. Some machines may promise high output but consume excessive power. Weighing the upfront cost against long-term operational expenses is wise.

Not all bentonite crushers are created equal in performance. Some may work well in specific applications but fail in others. Test various options before making a final decision.

When choosing a bentonite crusher, maintenance and support play a crucial role. Regular servicing helps prevent early wear and tear. Reports indicate that poor maintenance can reduce equipment life by up to 30%. Finding a supplier who offers reliable support is key. A responsive customer service team can help troubleshoot issues quickly, minimizing downtime.

One important aspect is the availability of spare parts. Delays in obtaining replacements can lead to prolonged interruptions. Research shows that efficient parts delivery can cut maintenance downtime by 20%. A network of service technicians nearby improves accessibility to support. It's wise to inquire about these elements before making a decision.

Here’s a tip: Always keep an eye on machine performance. Track operational efficiency regularly. Signs of inefficiency may indicate maintenance needs. Consider scheduling periodic check-ups, even if no issues seem apparent. This proactive approach pays off in the long run, ensuring smoother operations and better investment returns.