Choosing the right Hydraulic Stone Crusher is crucial for efficiency and productivity. In 2022, the global stone crushing equipment market was valued at over $4.3 billion. This highlights the industry's growth and the demand for advanced machinery. Hydraulic Stone Crushers have become popular due to their enhanced efficiency and ease of operation.

However, selecting the best model requires careful consideration. Factors such as capacity, durability, and cost must be weighed. A recent report indicated that nearly 30% of operators struggle with inefficiency due to improper equipment choice. This can lead to significant downtime and increased operational costs.

It's essential to evaluate the specific needs of your projects. Not all Hydraulic Stone Crushers offer the same performance. Research shows that models with adjustable settings are more versatile. Choosing wisely can prevent future headaches and ensure your operations run smoothly.

When selecting a hydraulic stone crusher, various factors come into play. Understanding these factors can significantly enhance efficiency and performance. One of the primary considerations is the crushed material type. Different stones require different levels of force and design. For instance, softer materials may not need the same hydraulic pressure as harder rock types.

Additionally, operational capacity is crucial. A crusher that can handle the expected volume without constant breakdowns is essential. Often, companies overlook the importance of maintenance requirements. A machine that is easy to maintain can save time and resources in the long run. Efficiency can also be influenced by the crushing method employed. Some methods tend to waste more energy than others, leading to higher operational costs.

Moreover, the weight and portability of the machine can impact your operations. A heavier unit may be more stable but less mobile. This could lead to inefficiencies when moving between sites. Thoughtful consideration of these factors can guide you toward making the best choice for your specific needs.

When selecting a hydraulic stone crusher, understanding key specifications is vital for optimal performance. Focus on the crushing capacity, which can vary significantly. Most machines operate within a range of 40 to 300 tons per hour. This metric reflects both the machine's efficiency and your project's demands.

Power consumption is another crucial factor. The more powerful a crusher, the better the output efficiency. Reports indicate that modern hydraulic models typically require between 200 kW to 600 kW, depending on their capacity. However, higher power does not always equal better performance. Sometimes, machines with lower power ratings are better suited for specific tasks, providing a balance between energy use and productivity.

It's also important to consider the hydraulic design and maintenance requirements. Advanced models may feature automatic lubrication systems, reducing manual intervention needs. However, such systems can complicate maintenance, and this should be weighed against operational habits. Many operators overlook the long-term service costs associated with these features, which can lead to unexpected expenses.

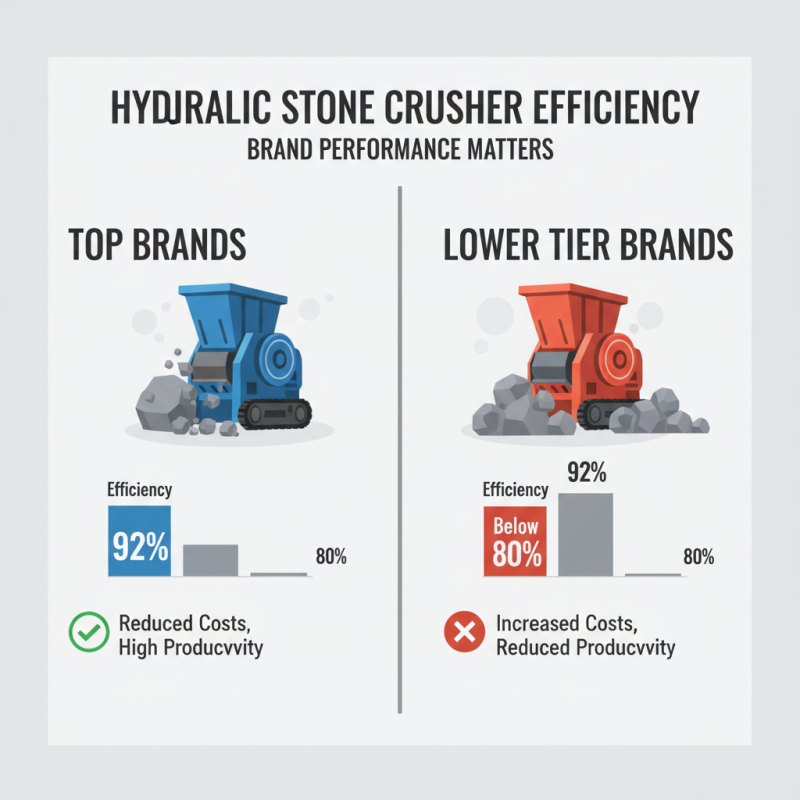

When selecting a hydraulic stone crusher, understanding brand performance is critical. A recent industry report indicated that the efficiency of hydraulic systems can vary dramatically by brand. Some manufacturers boast operational efficiencies as high as 92%. However, others lag significantly, with efficiency ratings below 80%. This disparity can lead to increased operating costs and reduced productivity.

Another essential aspect is the durability of the machine. Brands differ substantially in terms of material quality. For instance, a study revealed that certain crushers experienced wear rates 30% higher than their premium counterparts. This can result in frequent maintenance and costly repairs. Many users overlook these details during selection, focusing instead on initial cost rather than long-term value.

The user experience also varies. Operator feedback shows that certain models are more user-friendly. Intuitive controls can enhance productivity. In contrast, complex machines can frustrate operators, leading to mistakes and downtimes. Understanding these nuances can aid buyers in making an informed decision, ultimately affecting their operational success.

The demand for hydraulic stone crushers in the construction industry is growing rapidly. These machines are essential for breaking down large rocks into manageable sizes. Construction companies are increasingly utilizing hydraulic stone crushers for their efficiency and power. However, choosing the right one is crucial.

Market trends suggest a shift towards more compact and mobile models. These are easier to transport and can fit into tighter job sites. Customers are also looking for machines that offer better fuel efficiency. This trend reflects a broader commitment to sustainability. Yet, some buyers focus solely on price, which can lead to regrettable choices.

It’s important to test a machine before purchasing. Feel its strength and assess its operation. Buyers should consider their specific needs and not rely solely on brand reputation. A thorough analysis of features can prevent headaches later on. Remember, the best hydraulic stone crusher is one that meets your site requirements effectively.

Investing in hydraulic stone crushers can significantly impact your operations. A cost-benefit analysis is vital in this decision. Upfront costs may seem high. However, consider maintenance savings over time. Efficient machines reduce the need for frequent repairs.

Operational costs are another crucial factor. Hydraulic crushers typically consume less energy. This leads to reduced utility bills. However, you should evaluate the performance of various models. Not all machines offer the same efficiency. Research is necessary to avoid financial pitfalls.

It's essential to think about productivity. A more efficient stone crusher can process more material in less time. But, don’t overlook potential downtime. Sometimes, these machines require unexpected repairs. Assess the risks versus rewards carefully. Your choice should align with your project goals and budget constraints.

| Tip | Description | Cost (in $) | Expected Lifespan (Years) | Maintenance Cost (Annual) |

|---|---|---|---|---|

| 1. Evaluate Capacity | Consider the crushing capacity required for your operations. | 20,000 | 10 | 2,000 |

| 2. Assess Power Requirements | Match the power requirements with your existing infrastructure. | 25,000 | 12 | 2,500 |

| 3. Evaluate Mobility | Decide if a stationary or portable crusher is best for your needs. | 30,000 | 8 | 1,800 |

| 4. Check for Automation Features | Look for features that enhance operational efficiency. | 35,000 | 10 | 3,000 |

| 5. Analyze Safety Features | Prioritize crushers with safety mechanisms to protect workers. | 40,000 | 15 | 2,200 |

| 6. Look for Warranty and Support | Consider warranty terms and customer support availability. | 28,000 | 10 | 1,500 |

| 7. Research Materials Compatibility | Ensure the crusher can handle the materials you intend to crush. | 22,000 | 11 | 2,800 |

| 8. Read Customer Reviews | Analyze feedback from other users for real-world performance insights. | 34,000 | 13 | 1,700 |

| 9. Check for Compliance Standards | Ensure that crushers meet local and international safety standards. | 30,000 | 9 | 2,500 |

| 10. Calculate Total Cost of Ownership | Evaluate both upfront and ongoing costs to understand true investment. | 50,000 | 20 | 3,600 |