Efficient operation of a Mineral Crusher is crucial for the mining industry. In 2022, the global mineral processing market was valued at approximately $70 billion. This figure highlights the importance of optimal equipment performance. A Mineral Crusher not only breaks down raw materials but also influences production costs and operational efficiency.

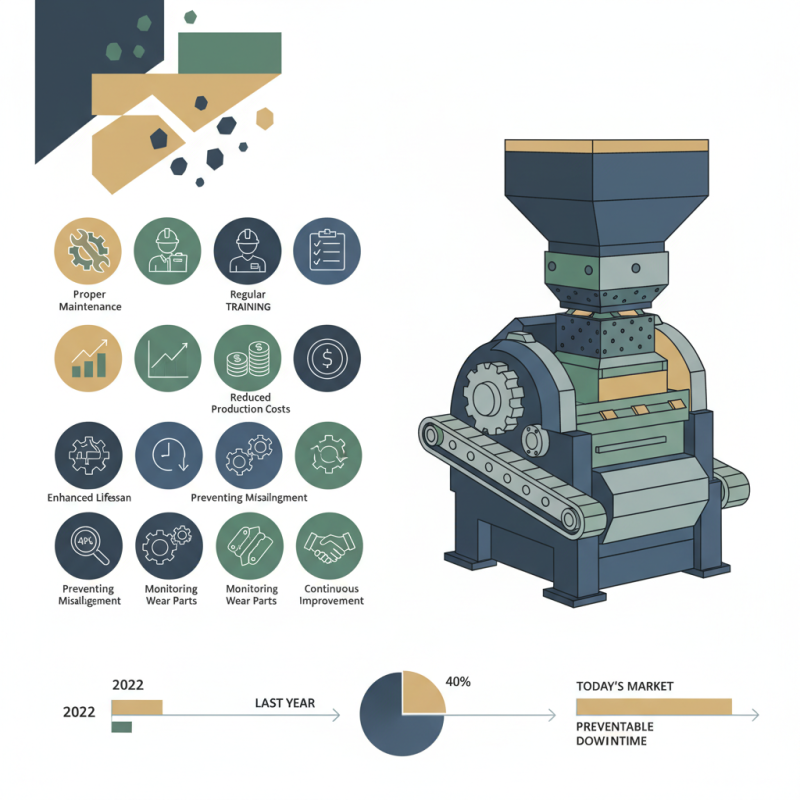

Proper maintenance and operational techniques can enhance the lifespan of these machines. However, many companies still face challenges in achieving peak efficiency. Engaging in regular training and adopting best practices can be a game changer. Last year, a survey indicated that 40% of operators lacked adequate training in equipment management. As a result, this led to increased downtime and reduced output.

Understanding the complexities of a Mineral Crusher is vital. Misalignment and poor wear parts can cause severe inefficiencies. An analysis of maintenance logs from various operations revealed that up to 30% of downtime was preventable. Continuous improvement and reflection on operational practices are necessary for success in today’s competitive market.

Operating a mineral crusher requires a firm understanding of basic principles. A mineral crusher’s role is critical in the mining and extraction industry. It reduces large rocks into smaller sizes, making them easier to manage. According to industry reports, efficient crushers can improve productivity by up to 25%. However, many operators overlook maintenance needs, leading to decreased efficiency.

Tip: Regular maintenance checks are crucial. Inspect wear parts, lubricate components, and ensure proper alignment. Neglecting these can result in costly downtime. The average cost of unscheduled maintenance in the mining sector can exceed $300,000 annually. This highlights the importance of taking care of your equipment.

Understanding the characteristics of the material being crushed is essential. Different minerals have varying hardness levels. For instance, limestone is softer than granite. Tailoring your approach based on this information can optimize efficiency. Adjusting the crusher settings to match material specifications can increase output quality and quantity. It's easy to become complacent and use default settings, but this often leads to inefficiencies.

Operating a mineral crusher efficiently is crucial for maximizing productivity. Key factors influence crusher efficiency significantly. One major factor is the material being processed. Harder materials require more power and wear out components quicker. Understanding the properties of the material can lead to better choices in equipment and settings.

Tip: Regular maintenance is essential. Lubricate moving parts and replace worn-out components promptly. This prevents breakdowns and ensures smooth operation. Operators often overlook minor issues until they escalate. Ignoring these can lead to inefficient performance.

Another factor is the crusher's settings. Correct settings can reduce energy consumption and improve output size. Check and adjust the gap settings regularly. Tip: Implementing a feedback system can help identify operational inefficiencies. However, this requires a bit of trial and error to fine-tune effectively. It’s important to reflect on these adjustments regularly. Understanding what works and what doesn’t is key to long-term efficiency gains.

This bar chart illustrates the key factors influencing crusher efficiency, along with their impact expressed in percentage. Maintenance frequency and material quality are the most significant factors, whereas operator skill and waste reduction have minimal impact.

Routine maintenance is crucial for the optimal performance of a mineral crusher. Regular checks can significantly reduce unexpected downtime. Industry reports show that proper maintenance can improve efficiency by up to 30%. This means less time spent on repairs and more time crushing.

Daily inspections should include checking belts, lubricating bearings, and monitoring the condition of wear parts. Even small wear can lead to larger issues later. For instance, a worn-out liner can decrease the crushing efficiency and lead to excessive power consumption. Missing this can be costly.

Further, operators should establish a maintenance log. This log helps in tracking issues over time. Reports indicate that companies with well-documented maintenance protocols reduce operational costs by around 20%. Regularly scheduled maintenance tasks help identify patterns. Data suggests that an effective maintenance strategy can extend equipment lifespan by 15-25%. When maintenance is overlooked, minor problems escalate quickly. Regular upkeep is not just about compliance; it's vital for efficiency and cost savings in the long run.

Operating a mineral crusher is not without its challenges. One significant issue is equipment wear and tear, which can affect efficiency. According to a report by the International Journal of Mineral Processing, over 60% of operational downtime is due to equipment failure. Regular maintenance is crucial. Skipping routine checks can be costly in the long run. Delaying repairs often leads to major breakdowns that halt production.

Another common challenge is the variability of raw materials. Each batch can differ in hardness and moisture content. The US Geological Survey shows that up to 25% of crushing inefficiencies arise from material inconsistencies. Operators must remain vigilant. They need to adjust settings based on incoming material. Ignoring these variations can lead to decreased throughput and increased energy costs.

Fuel efficiency is also an often-overlooked area. Many operations don’t optimize power usage during crushing. A study from the Society for Mining, Metallurgy & Exploration notes that energy costs can represent up to 30% of total operational expenses. Monitoring energy usage can uncover inefficiencies. By doing so, operators can identify potential savings and improve overall productivity in their crushing operations.

Safety is paramount in mineral crushing operations. Operators must wear appropriate personal protective equipment. Helmets, gloves, and eye protection can prevent serious injuries. Regular safety training sessions can ensure everyone knows the risks involved. This not only promotes awareness but also builds a safety-first culture.

Regular inspections of the crusher equipment are essential. Checking for wear and tear can prevent accidents. Operators should be encouraged to report any irregularities immediately. Yet, some might hesitate due to fear of repercussions. It's crucial to foster an environment where concerns can be shared freely.

Establish clear communication protocols between team members. Using walkie-talkies or other devices can help maintain safety during operation. However, reliance on technology can sometimes be a double-edged sword. Miscommunication can lead to accidents. Continual evaluation of communication methods will aid in enhancing safety measures.