In today's construction and demolition industries, the Granite Crusher plays a crucial role. This powerful machine breaks down granite into manageable pieces for various applications. Knowing how to use it effectively can make a significant difference in project success. Proper usage can improve efficiency and reduce costs.

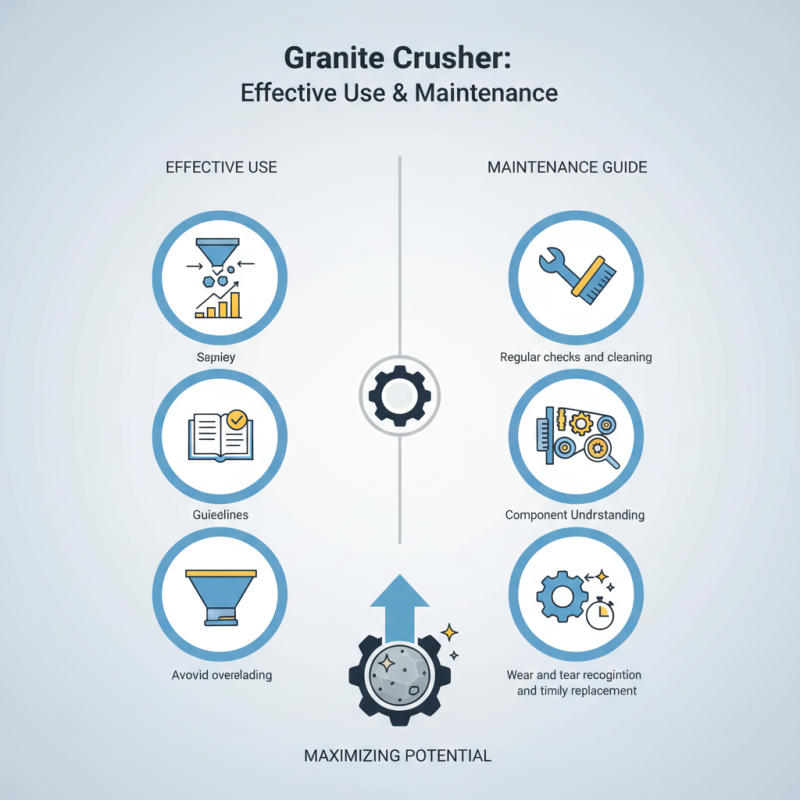

However, many users encounter problems due to negligence in maintenance. A poorly maintained Granite Crusher may lead to mechanical failures. Regular checks and cleaning can prevent such issues. It's essential to understand the components of the machine. Recognizing wear and tear is important.

Consider the common mistakes made when operating a Granite Crusher. Overloading the machine can cause damage and decrease its lifespan. Users often ignore operational guidelines too. It's vital to reflect on these practices to enhance performance. By focusing on proper use and maintenance, professionals can maximize the potential of their Granite Crusher.

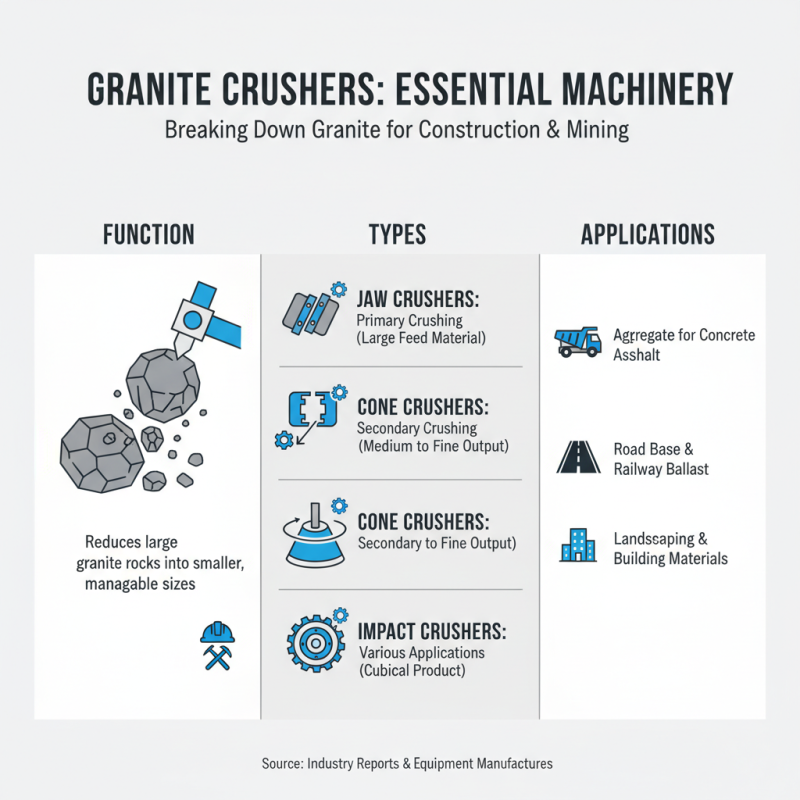

Granite crushers are essential machinery in construction and mining industries. They break down granite into smaller pieces, making it suitable for various applications. These crushers come in different types, including jaw, cone, and impact crushers. Each type serves a specific purpose. For instance, jaw crushers are effective for primary crushing, while cone crushers handle secondary crushing tasks efficiently.

Granite has unique properties that pose challenges. Its hardness requires robust machinery. Operators often face difficulties in setting the right parameters. This can lead to inefficient crushing or equipment damage. Regular maintenance is crucial for peak performance. Monitoring wear parts helps prevent unexpected breakdowns. Users should also consider the material characteristics before selection. Understanding granite's composition can help optimize the crushing process.

When selecting a granite crusher, key features can make a notable difference. Pay attention to the crushing capacity. A higher capacity allows for quicker processing of material. This can be important for larger projects. Look for adjustable settings as well. This enables better control over the final product size.

Durability is another crucial aspect. A sturdy build can withstand heavy use and rough conditions. Check the materials used in construction. Steel components often last longer than others. Regular maintenance, however, is essential. It can be easy to overlook.

Tips for effective use include proper loading techniques. Avoid overloading the machine to enhance performance. Monitor your equipment regularly to catch any irregularities early. Be aware of noise levels too. Unusual sounds can signal mechanical issues requiring immediate attention. Small changes in practice can lead to significant improvements over time.

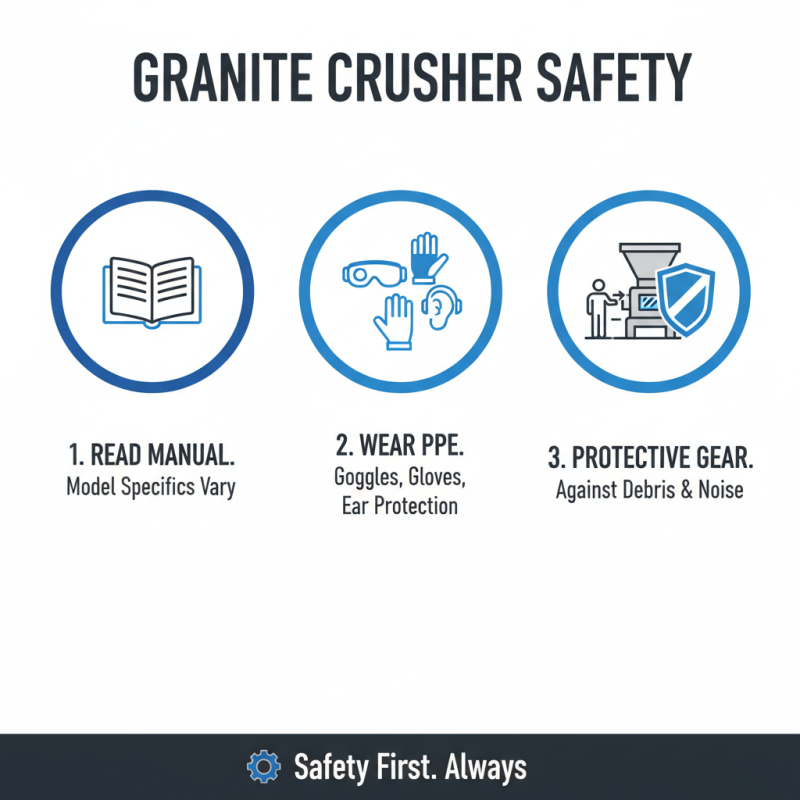

Operating a granite crusher requires attention to detail and safety. Start by reading the manufacturer’s instructions carefully. Each model may operate differently. Safety gear is essential: wear goggles, gloves, and ear protection. This will protect you from debris and loud noise.

When using the crusher, feed it small, manageable rocks. Large pieces can cause blockages. Ensure the machine is on stable ground to prevent tipping. Check the crushing chamber regularly for blockages. A stuck rock can lead to significant downtime and expensive repairs.

Maintenance is often overlooked but crucial. Regularly lubricate moving parts to ensure smooth operation. Inspect the belts for wear and tear. Replace them as needed to avoid unexpected breakdowns. Cleaning the machine after use prevents rust and damage. Neglecting these tasks can lead to future issues and costly repairs. Make it a habit to check everything before and after use, ensuring your equipment lasts longer and operates safely.

Proper maintenance of granite crushers is crucial for optimal performance. Regular inspections help catch issues before they escalate. Check for wear on the crushing surfaces. A cracked component can lead to significant downtime. It’s essential to monitor oil levels; low oil can cause overheating. Always keep the equipment clean. Dust and debris can hinder performance.

In addition to routine checks, implement a lubrication schedule. Different parts need different lubrication frequency. Follow the manufacturer’s guidelines, but adjust based on usage. If you notice excessive wear, revisit your operating procedures. Are you overloading the machine? This can lead to faster degradation.

Educate your team on best practices. A well-trained operator can identify early warning signs. Encourage reflections on past maintenance efforts. Were there missed opportunities for improvements? A culture of continuous learning leads to enhanced efficiency. Regularly revisiting your maintenance strategies is key.

Granite crushers are vital in various industries. However, they can encounter common issues that need attention. For example, improper feed can cause blockages. In fact, studies show that nearly 30% of downtime is due to material jams. Owners should ensure they follow the recommended feed sizes. This can significantly reduce issues.

Another common problem is excessive wear on components. Regular maintenance is crucial here. Studies indicate that proactive maintenance can extend equipment life by 20%. Check parts like hoppers and jaws regularly. If you notice irregular wear patterns, reassess your operation methods. Often, improper alignment leads to uneven wear, affecting performance.

Vibrations are also a concern. Manufacturers state that high vibration levels can indicate various internal problems. Monitoring devices are available to track this. A small crack or defect may grow if unnoticed. Regular inspections can prevent costly repairs. Ignoring these details could lead to major failures. Be prepared to adapt and evolve your maintenance practices for optimal efficiency.

| Dimension | Details | Best Practices | Common Issues | Troubleshooting Tips |

|---|---|---|---|---|

| Size Reduction Ratio | Typically 4:1 to 6:1 | Maintain optimal feed size | Overly large feed material | Adjust feed material size |

| Operating Temperature | Should not exceed 75°C | Regular maintenance of cooling system | Overheating | Check fluid levels and vents |

| Daily Checks | Lubrication and wear parts inspection | Follow maintenance schedule | Excessive wear or noise | Replace worn parts promptly |

| Water Use | Optimal moisture level around 5% | Monitor water usage | Clogging due to excessive water | Adjust water feed system |

| Safety Checks | Ensure all safety guards are in place | Conduct regular training sessions | Malfunctioning safety doors | Inspect and repair immediately |