When it comes to constructing durable and aesthetically pleasing structures, the choice of materials plays a crucial role. Among various options, granite stands out due to its strength, resistance to weathering, and timeless beauty. However, in order to harness the full potential of granite, selecting the right granite crusher becomes imperative. A granite crusher is not only essential for breaking down large blocks of granite into manageable sizes but also influences the efficiency of operations, quality of the final product, and overall cost-effectiveness. As the construction and landscaping industries evolve, understanding how to choose the best granite crusher tailored to specific needs is essential for professionals and DIY enthusiasts alike.

In this guide, we will explore the critical factors that can assist in making an informed choice when selecting a granite crusher. From the different types of crushers available, to the technological advancements that have enhanced their capabilities, each aspect will be examined in detail. By bringing these elements to light, we aim to equip you with valuable insights, ensuring that your investment in a granite crusher aligns with your project requirements. Whether you're involved in large-scale construction or intimate landscaping projects, having the right tools at your disposal is key to achieving your vision with granite.

Granite crushers are essential machines in the mining and construction industries, designed to break down large granite rocks into manageable sizes for various applications. Understanding the different types of granite crushers is crucial for selecting the right one for your specific needs. The most common types include jaw crushers, cone crushers, and impact crushers. Each type serves distinct functions; for instance, jaw crushers are typically used for primary crushing, while cone crushers are more suited for secondary and tertiary crushing operations. According to industry reports, the global demand for granite crushers is projected to grow by 6% annually, driven by increasing construction activities and the need for high-quality aggregates.

When choosing a granite crusher, consider the material's hardness and the desired output size. Granite’s compressive strength averages around 100-250 MPa, making durable machines vital in effectively handling its tough structure. Additionally, understanding the intended application is key—whether for road construction, concrete production, or decorative stone. It’s also essential to factor in maintenance costs and machine efficiency, as these can significantly influence overall operational expenditure.

Tips: Always consult with industry professionals to gain insights into the latest technology and models that align with your operational requirements. Additionally, analyze your production requirements—knowing the expected throughput can guide you in choosing the appropriate size and type of crusher. Regular maintenance can also extend the life of your equipment and ensure optimal performance.

When selecting a granite crusher to meet your specific needs, it’s crucial to evaluate several key factors that can significantly influence performance and efficiency. Firstly, the size of the granite stones you’ll be processing plays a vital role. Different crushers are designed to handle varying sizes of input material. Ensuring that the machine can accommodate your granite’s size will help in achieving optimal crushing results and minimizing downtime.

Another important factor is the crushing capacity of the equipment. This refers to how much material the crusher can process within a given timeframe. Understanding your operational requirements, such as the volume of granite to be crushed and the desired output size, will assist in choosing a crusher that aligns with your production goals. Additionally, consider the machine's power requirements and energy efficiency, as this can affect long-term operating costs.

Lastly, focus on the maintenance and durability of the granite crusher. Machines with tough construction and the ability to withstand harsh working environments will not only reduce maintenance frequency but also extend the lifespan of your equipment. Evaluating factors such as warranty and support can also provide insights into the reliability of the machine you intend to purchase. By carefully considering these aspects, you can select a granite crusher that will effectively meet your needs while ensuring cost-efficiency and high performance.

When selecting a granite crusher, the variety of models on the market can be overwhelming. This comparative analysis focuses on key features and performance metrics of popular models to help you make an informed choice. Factors such as crushing capacity, mobility, and ease of maintenance are crucial in determining the best fit for your specific needs. Some models are designed for heavy-duty tasks, while others prioritize portability, making them suitable for smaller projects or diverse job sites.

Tip: Consider your project's scale and location when choosing a granite crusher. If you're working on a large-scale operation, you might prioritize high capacity and durability. However, for smaller jobs or those requiring frequent relocation, a lightweight, compact model could be more advantageous.

Additionally, energy efficiency and operational costs should not be overlooked. Some models incorporate advanced technology for reduced fuel consumption and lower maintenance expenses over time. Assessing these elements can provide long-term savings and sustainability in your operations.

Tip: Conduct thorough research on each model's specifications and user reviews, focusing on long-term reliability and performance to ensure you invest wisely in your crushing equipment.

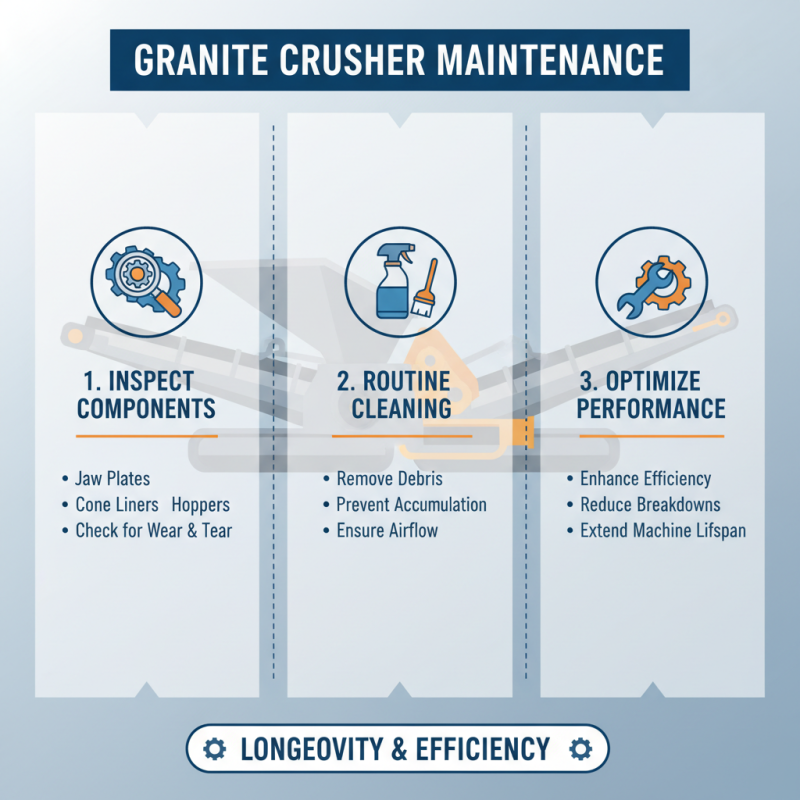

Maintaining your granite crusher is essential for ensuring its longevity and optimal performance. Regular maintenance can prevent potential breakdowns and enhance efficiency. Start by regularly inspecting key components such as the jaw plates, cone liners, and hoppers for signs of wear and tear. Routine cleaning is equally important; debris can accumulate and hinder the machine's operations. A clean, well-maintained machine operates more efficiently and reduces the risk of overheating and other mechanical issues.

Additionally, lubrication plays a crucial role in the maintenance of your granite crusher. Ensure that all moving parts are adequately lubricated according to the manufacturer's recommendations. This reduces friction and wear, ultimately prolonging the life of the machine. It's also advisable to check and replace filters and fluids as needed, as this will help maintain peak operational performance. Keeping a detailed maintenance log can assist you in tracking wear patterns and scheduling repairs, ultimately leading to a more efficient and reliable granite crushing operation.

When considering the purchase of a granite crusher, understanding cost implications and budgeting strategies is crucial for businesses looking to maximize their investment. According to a recent report from the National Stone, Sand & Gravel Association (NSSGA), the average cost of granite crushers can range significantly based on factors such as capacity, technology, and additional features. On average, prices can vary from $50,000 to over $300,000, depending on the specific requirements of the operational environment. Additionally, maintenance costs, which typically account for about 10-15% of the initial purchase price annually, should be factored into the overall budget.

Proper budgeting for a granite crusher also involves planning for operational costs including energy consumption, labor, and wear parts. A 2020 study by the Institute of Quarrying found that energy costs can represent up to 30% of the total operating expenses associated with crushing operations. Therefore, selecting a model that is energy-efficient can lead to significant long-term savings—research indicates that electric models can save companies as much as 20% on their energy bills compared to conventional diesel-powered units. By carefully assessing initial and ongoing costs, businesses can ensure they choose a granite crusher that meets their operational needs while aligning with their financial capabilities.

| Model | Type | Capacity (tons/hour) | Price ($) | Power (kW) | Weight (kg) |

|---|---|---|---|---|---|

| Crusher A | Jaw Crusher | 50 | 15,000 | 75 | 2,500 |

| Crusher B | Cone Crusher | 100 | 25,000 | 110 | 3,000 |

| Crusher C | Impact Crusher | 70 | 18,500 | 90 | 2,800 |

| Crusher D | Gyratory Crusher | 120 | 30,000 | 150 | 4,500 |