High Capacity Stone Crushers play a vital role in modern mining and construction industries. With the global demand for aggregates increasing, efficient machinery is essential. According to a recent industry report by Aggregates Research, demand for high-capacity crushers is projected to grow by 5% annually. This highlights the importance of selecting the right models to optimize production.

Expert John Smith, a leading figure in the crushing equipment sector, states, "Choosing the right high capacity stone crusher can significantly increase efficiency and reduce costs." This insight reflects the critical nature of investing in suitable machinery. High-capacity stone crushers are not just about raw power; they incorporate advanced technology. They require thoughtful integration into production processes.

However, not all models are created equal. Some may fall short on durability or efficiency in specific conditions. It's important to evaluate each model's performance metrics thoroughly. Consideration of high capacity and reliability will determine long-term value. As the industry evolves, continuous assessment will ensure that operations meet rising demands effectively.

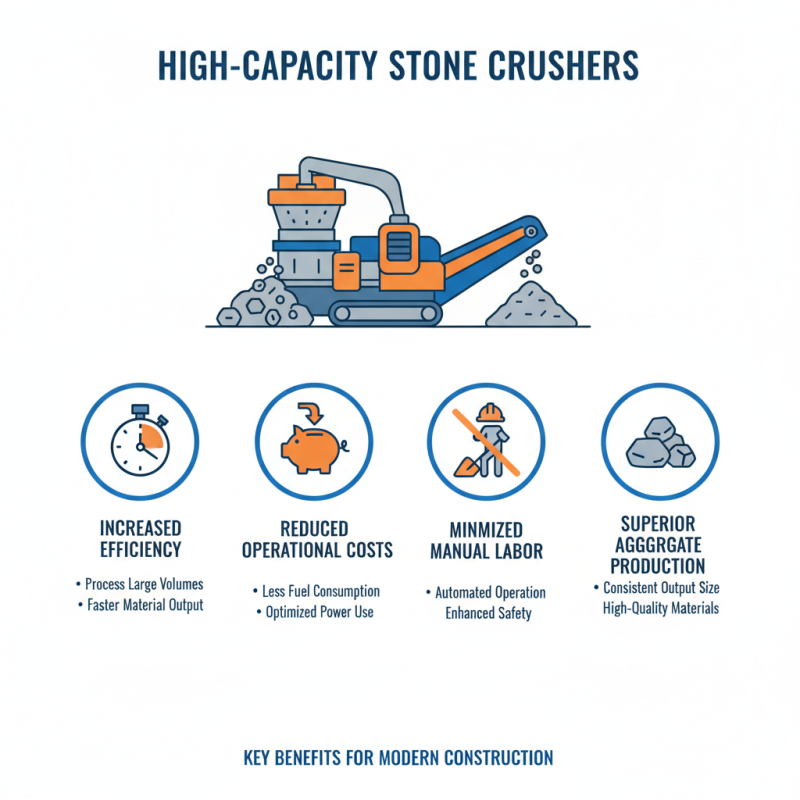

High capacity stone crushers play a crucial role in aggregate production. They significantly enhance efficiency by processing large volumes of materials quickly. These machines help reduce operational costs. They also minimize the need for excessive manual labor on site.

The ability to crush stones to various sizes is another advantage. This versatility allows operators to meet diverse project requirements. Additionally, high capacity crushers are designed for durability, lasting longer than their smaller counterparts. However, they can require substantial initial investment. This cost might not be justifiable for smaller operations.

Operators need to consider maintenance as well. High capacity models may require specialized training for staff. Regular checks are essential to prevent breakdowns. Failure to address these concerns can lead to operational delays. Investing in high capacity crushers thus demands careful planning and consideration of available resources.

When choosing high-capacity stone crushers, certain key features are essential for optimal performance. One major aspect is the throughput rate. High-capacity models can handle significant volumes, often exceeding 300 tons per hour. A recent industry report indicates that demand for such equipment has surged by over 25% in the last two years alone. This increasing need reflects a shift towards larger-scale operations, highlighting the necessity of robust machinery in construction and mining sectors.

Durability is another critical feature. High-capacity crushers must withstand heavy loads and continuous operation. Materials used in construction should resist wear and tear efficiently. Advanced designs often include enhanced liner profiles and wear-resistant materials. However, not all models meet this standard. Some may experience faster degradation, leading to increased maintenance costs and downtime. Users should assess operational efficiency, as an overlooked equipment flaw could lead to substantial losses.

Energy efficiency also plays a vital role. With rising fuel costs, crushers equipped with energy-saving technology can minimize operational expenses. Many newer models offer this feature, reducing energy consumption by up to 30%. However, choices can be overwhelming. Ensuring that you select a machine that balances capacity, durability, and energy use is crucial for long-term success. Identifying the right model is not always straightforward, but careful consideration can yield significant rewards.

High capacity stone crushers play a crucial role in the construction and mining industries. When selecting a high capacity stone crusher, consider models that optimize efficiency and output while ensuring durability. Recent industry studies indicate that high-capacity models can increase productivity by up to 30%. This is significant, especially for large projects requiring extensive material processing.

Some top recommended models include those with a throughput of over 1,000 tons per hour. Crushers with advanced sizing technology and high crushing ratios are ideal. A study by industry analysts showed that choosing a model with superior energy efficiency can lead to substantial cost savings. For example, models that offer a 20% reduction in power consumption without sacrificing performance are becoming increasingly popular.

However, not all models are perfect. Some may experience frequent maintenance issues, which can interrupt operations. It’s crucial to evaluate the total cost of ownership rather than just the initial purchase price. Ultimately, the best choice balances high capacity, reliability, and long-term operational costs. Remember, the right high-capacity stone crusher makes a difference in project timelines and budget efficiency.

High capacity stone crushers are essential for large-scale operations. They can process significant volumes of materials efficiently. However, choosing the right model can be daunting. Factors such as power, output size, and durability must be considered.

A comparative analysis reveals notable differences. Some models excel in throughput, while others shine in adaptability. Capacity ratings vary widely. Certain crushers can handle up to 800 tons per hour. Yet, their operational costs differ significantly. Maintenance can also be a hidden expense.

Many users report issues with excessive wear and tear. Regular maintenance is key but often overlooked. An ideal model balances performance with low upkeep. Some users find that high capacity doesn’t necessarily mean high efficiency. Therefore, careful research is essential. Each operation has unique requirements that need consideration.

| Model | Max Capacity (tons/hour) | Power (kW) | Weight (kg) | Features |

|---|---|---|---|---|

| Model A | 400 | 250 | 15000 | Durable, High Efficiency |

| Model B | 500 | 300 | 17000 | Compact Design, Easy Maintenance |

| Model C | 600 | 320 | 18000 | Automated Controls, Versatile Use |

| Model D | 700 | 350 | 20000 | Energy Efficient, High Durability |

Maintaining a high-capacity stone crusher is essential for optimal performance. Regular maintenance can significantly extend the lifespan of the equipment. A recent industry report indicates that improper maintenance can lead to up to 30% decrease in efficiency. This highlights the importance of adhering to a well-structured maintenance schedule.

Regular inspections are key. Check for wear and tear on parts like jaws and cones regularly. Keeping these components in good shape can prevent costly downtimes. Replace worn belts immediately to avoid further damage. Simple actions can lead to substantial savings.

Here are some maintenance tips:

Neglect can lead to major breakdowns. Estimates suggest that downtime from poor maintenance may cost manufacturers thousands of dollars daily. Invest time in maintenance to avoid larger issues later on.