In the fast-evolving construction industry, the demand for durable and efficient materials has never been more crucial. As projects grow in scale and complexity, investing in a Granite Crusher becomes not just beneficial, but essential for contractors aiming to enhance their operational capability. According to industry expert John Stevens, a seasoned geotechnical engineer with over 20 years of experience, "A Granite Crusher is a cornerstone investment for construction companies looking to maximize productivity and ensure the longevity of their projects."

With its unmatched versatility and strength, granite has become a go-to aggregate material in modern construction. Whether for infrastructure development, landscaping, or high-rise buildings, a Granite Crusher allows companies to efficiently process and recycle granite into usable aggregates, significantly reducing costs and improving project timelines. The strategic implementation of this equipment not only aids in meeting the rigorous demands of construction but also contributes to sustainable practices by minimizing waste and optimizing resource use. Embracing a Granite Crusher can thus be seen as a forward-thinking move that positions businesses for success in a competitive market.

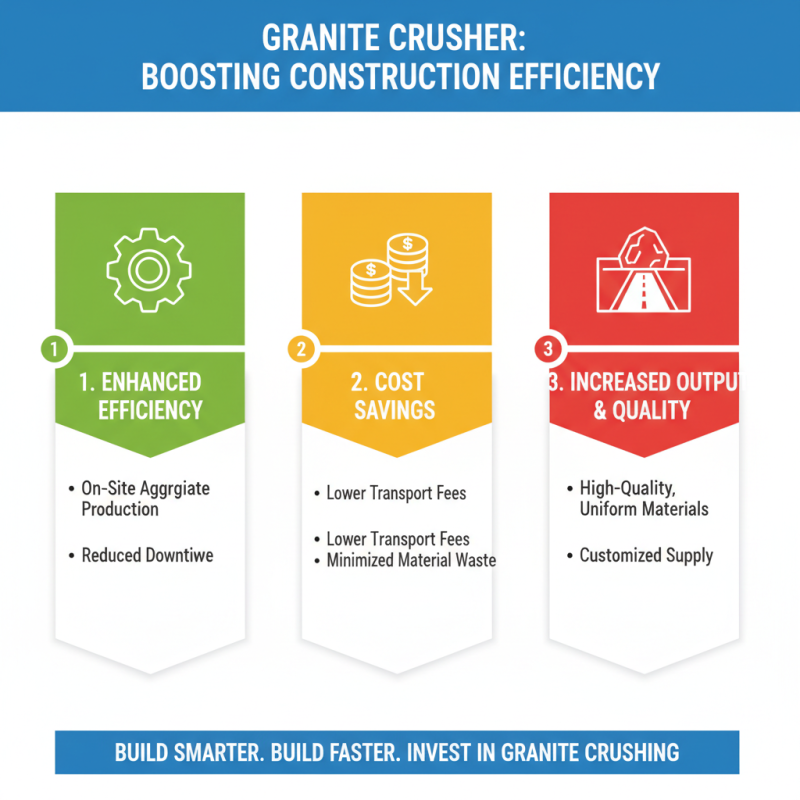

Investing in a granite crusher can significantly enhance the efficiency and output of your construction projects. Granite is a durable and versatile material widely used in building infrastructure, roadways, and decorative features. A dedicated granite crusher allows construction businesses to produce high-quality aggregates on-site, which saves time and reduces transportation costs. By utilizing a granite crusher, companies can ensure they have a steady supply of materials customized to their specific project requirements.

Another key benefit lies in the crusher's ability to minimize waste. Granite, being a robust stone, can be recycled and repurposed for various construction needs. By crushing leftover or unused granite, companies can create new aggregate materials, reducing landfill contributions and supporting sustainable practices. Furthermore, a granite crusher allows for better control over the material quality, ensuring consistency and reliability in construction projects. Ultimately, investing in a granite crusher not only enhances productivity but also supports environmentally friendly construction practices.

Granite crushers play a crucial role in aggregate production, which is essential for various construction projects. According to the U.S. Geological Survey (USGS), crushed stone production reached approximately 1.5 billion tons in 2020, with granite accounting for a significant portion of this total. The versatility and durability of granite make it an ideal material for construction purposes, such as road building and concrete production. The efficiency of granite crushers facilitates the transformation of large granite boulders into aggregate sizes that cater to the industry's specific needs.

The operational efficiency of granite crushers directly impacts the quality and availability of aggregates. A study from the Aggregates and Quarrying Association indicates that the right crushing equipment can lead to a 30% increase in production efficiency while also reducing operational costs. With the rising demand for high-quality aggregates driven by construction projects and infrastructure development, investing in a reliable granite crusher can significantly enhance a company's productivity and profitability. Additionally, the ability to produce various aggregate sizes efficiently supports sustainable practices by minimizing waste and ensuring efficient resource usage in construction activities.

When considering the investment in a granite crusher, a thorough cost analysis reveals significant advantages over traditional methods. Traditional stone processing often relies on manual labor and less efficient machinery, leading to prolonged project timelines and higher labor costs. In contrast, utilizing a granite crusher streamlines the crushing process, allowing for faster production rates and reduced need for manpower. This efficiency often translates to lower overall project costs, as contractors can complete jobs quicker and take on more projects simultaneously.

Moreover, while the upfront investment in a granite crusher may seem substantial, the long-term savings are considerable. Maintenance and operational costs of modern crushers are typically lower than those associated with older, traditional methods. Additionally, granite crushers produce uniformly sized materials that minimize waste, further enhancing cost efficiency. By reducing the need for reprocessing and enabling more precise material usage, a granite crusher can enhance profitability over time, making it a wise investment for construction businesses aiming to optimize their operations.

| Method | Startup Costs | Operating Costs per Ton | Output per Day (Tons) | Labor Needed | Break-even Period (Months) |

|---|---|---|---|---|---|

| Granite Crusher | $150,000 | $5 | 200 | 2 | 10 |

| Traditional Method | $50,000 | $8 | 100 | 3 | 15 |

Investing in a granite crusher significantly enhances construction efficiency and productivity, playing a pivotal role in modern construction projects. According to a recent report by the National Stone, Sand & Gravel Association, crushed granite is among the most utilized aggregates in the construction sector, contributing to nearly 30% of all aggregate production in the United States. This high demand is largely due to granite's durability and aesthetic appeal, making it an ideal choice for various applications, from road construction to high-rise buildings.

The incorporation of granite crushers into construction operations not only streamlines the material preparation process but also boosts productivity. A study from the Construction Industry Institute revealed that projects employing advanced crushing technology can reduce material processing time by up to 25%. This improvement allows for faster project completion and can decrease overall labor costs, as fewer workers are needed for crushing and processing materials on-site. Additionally, crushed granite provides consistent quality and size, which is crucial for maintaining structural integrity and meeting regulatory standards. With these benefits, investing in a granite crusher becomes a strategic decision for construction firms looking to enhance their operational effectiveness.

The construction industry is witnessing a significant surge in demand for granite crushers, driven by the growing need for durable and high-quality materials. As infrastructure projects continue to expand globally, construction companies are increasingly prioritizing robust raw materials, and granite stands out for its strength and resistance to wear. This shift highlights the necessity for efficient crushing equipment that can transform granite into aggregates suitable for a variety of applications, such as road construction, concrete production, and landscaping.

In recent years, market trends have indicated a consistent increase in the production and sale of granite crushers. Factors such as urbanization, population growth, and increased investment in public infrastructure have contributed to this demand. Additionally, advancements in technology have made modern granite crushers more efficient and cost-effective, allowing construction companies to improve their productivity and reduce operational costs. As a result, investing in a granite crusher not only meets the current demand but also positions businesses to capitalize on future opportunities within the construction sector.