The effectiveness of a Gold Ore Crusher can significantly impact mining operations. According to a report by Global Mining Review, nearly 70% of gold extraction efficiency hinges on the initial crushing phase. Utilizing the right techniques can lead to improved recovery rates, lower operational costs, and enhanced productivity.

Industry expert Dr. James While underscores the importance of this equipment in his analysis, stating, "A Gold Ore Crusher is not just a machine; it's a catalyst for maximizing mineral recovery." This perspective highlights the crucial role that operational precision plays.

Despite advances in technology, challenges remain. Operators often overlook maintenance protocols or miscalculate the optimal crushing size. Such oversights can hinder performance and lead to increased costs. Investing in training and awareness can bridge these gaps. A better understanding of the Gold Ore Crusher's mechanics and capabilities will greatly benefit mining ventures.

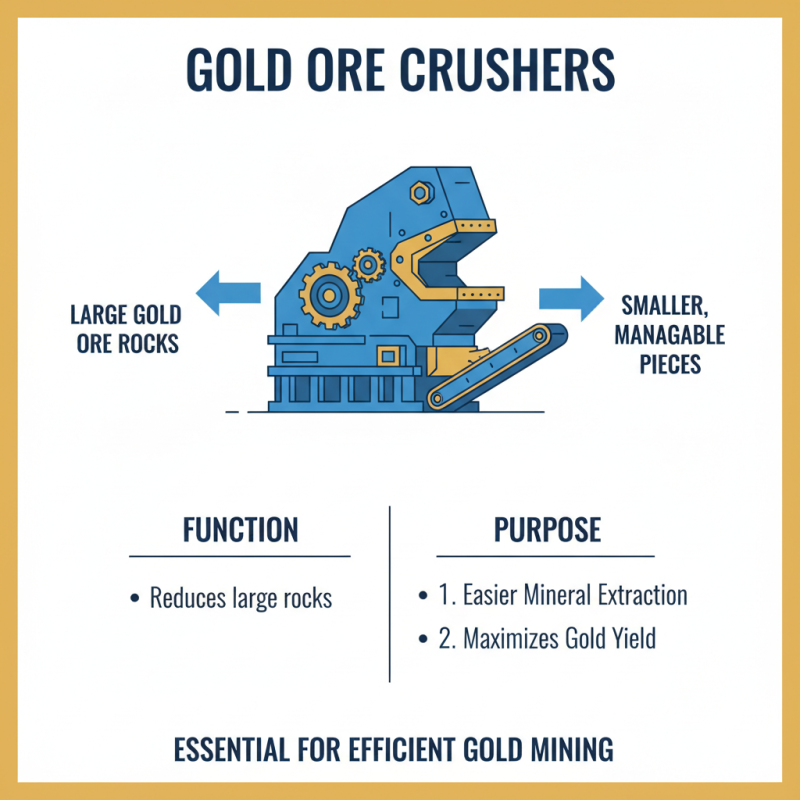

Gold ore crushers are essential tools in the mining and extraction process. Understanding how they work can help maximize their effectiveness. A gold ore crusher reduces large rocks into smaller, manageable pieces. This process makes it easier to extract valuable minerals from the ore.

One key component to consider is the type of crusher used. Different crushers serve various purposes, influencing the crushing process. Jaw crushers break down ores through compression, while cone crushers use a more refined approach. Knowing these distinctions helps in choosing the right crusher. Something often overlooked is maintenance. Regular checks ensure the machine operates efficiently. Neglecting maintenance could lead to unexpected breakdowns.

Operators need to monitor the crusher's output closely. An inconsistent output may indicate a problem. Observing the ore's feed quality is crucial as well. Poor quality can lead to unnecessary wear on the equipment. Training and experience are vital to optimizing these machines. However, mistakes can happen, and that's part of the learning process. Reflecting on those errors can lead to improvements in technique and efficiency.

When it comes to gold ore crushers, various types serve unique purposes. Jaw crushers are popular for their ability to crush large pieces of ore into smaller fragments. They generate significant force, making initial crushing effective. However, they may not achieve the finest particle size, which may require additional processing.

Cone crushers are another option, designed for secondary crushing. They produce a finer particle size and can handle harder materials. Yet, they may require more maintenance and can be less efficient with softer ores. It's important to choose the right type based on the characteristics of the ore being processed.

Impact crushers are also used for gold ore. These devices utilize high-speed impact to fracture the material. They work well for materials that are brittle but can be less effective on tougher ores. Operators should carefully evaluate the type of gold ore present before selecting a crusher. The effectiveness of the machine depends on the specific application and the nature of the ore.

This chart illustrates the effectiveness of different types of gold ore crushers based on their processing efficiency and application. The data demonstrates the comparison between primary, secondary, and tertiary crushers in terms of their average throughput (tons per hour) during the crushing process.

When using a gold ore crusher, several key factors can enhance crushing performance. The size of the feed material is crucial. Larger pieces may obstruct the crusher and cause inefficiency. Ideally, ore should be pre-crushed to a manageable size. This simple step can save energy and improve output.

Another factor to consider is the hardness of the ore. Different ores require different crushing techniques. Softer ores may need less force, while harder ones demand more power. Monitor the crushing process. Overloading the crusher can lead to damage and increased wear. Keep an eye on product size; it’s vital for downstream processes.

Operational maintenance is often overlooked but is essential for optimal performance. Regular checks on wear parts can avoid unexpected downtime. Sometimes, it’s easy to miss signs of wear until it's too late. Being proactive can minimize disruptions. Adjusting the crusher settings based on the material being processed is also important. Fine-tuning these settings can significantly impact the efficiency of the crushing operation.

Maintaining a gold ore crusher is essential for optimal performance. Regular maintenance ensures durability and efficiency. One key practice is to routinely check for wear and tear. Inspect the crushing chamber regularly. Look for signs of damage or excessive wear. If parts seem worn out, consider replacing them. This simple step can prevent bigger issues down the line.

Cleaning your crusher is another crucial step. Dust and debris can accumulate, affecting performance. Ensure that all moving parts are clear and free from obstruction. Lubrication is vital as well. Apply the right type of lubricant to all bearing areas. Neglecting this process can lead to seizing and breakdowns. However, remember that over-lubrication can also cause problems.

Monitoring operational parameters helps identify issues early. Excessive vibrations often signal a problem. Adjustments might be necessary to avoid potential damage. Keeping a maintenance log can help track issues and solutions. Learning from past mistakes is key. Reflecting on what went wrong can inform better practices in the future. Effective maintenance is not just about fixing but also about understanding the machine's needs.

| Technique | Description | Frequency | Recommended Action |

|---|---|---|---|

| Regular Inspection | Check all components for wear and tear. | Weekly | Replace worn parts immediately. |

| Lubrication | Ensure all moving parts are properly lubricated. | Monthly | Use recommended lubricant; check for leaks. |

| Material Feeding | Feed the crusher at a steady rate to avoid blockages. | Continuous | Use sensors to regulate feed rate. |

| Dust Control | Implement measures to control dust emission. | Daily | Use water sprays or dust suppressants. |

| Safety Checks | Conduct safety assessments and ensure emergency stops are functional. | Monthly | Train personnel on safety protocols and equipment use. |

Operating a gold ore crusher involves inherent risks. Safety must be the top priority. According to industry reports, more than 20% of mining accidents are related to equipment use. Proper knowledge and precautions can prevent these mishaps.

Wearing personal protective equipment is essential. This includes helmets, goggles, and gloves. Additionally, ensure that the work area is clear of hazards. A cluttered space increases the risk of accidents. Regular inspections of equipment can identify potential issues before they become serious.

When working with a gold ore crusher, it's critical to follow operational guidelines. Improper usage can lead to inefficient processing and equipment damage. Always check for loose components and ensure that the crusher is properly calibrated. Routine maintenance helps keep the crusher in safe working order.

Tips: Establish a clear communication system among operators. This can prevent misunderstandings during operations. Regular training on safety protocols is crucial. Engage workers in discussions about safety to enhance their awareness. Always be open to feedback and suggestions for improvement.