Limestone Crusher Machines play a vital role in the construction and mining industries. They are essential for processing limestone, a key material used in cement and road construction. According to a report by Grand View Research, the global limestone market is projected to reach $6.5 billion by 2025. This growth underscores the importance of efficient and advanced limestone crusher technologies.

Several features distinguish a high-performing Limestone Crusher Machine. For instance, machines equipped with robust crushing capabilities can handle various sizes of limestone. Data from Market Research Future indicates that machines with multi-functionality are becoming increasingly popular. They not only crush but also screen and separate materials effectively. However, not all machines meet these standards. Many lack durability or efficiency, leading to suboptimal performance.

In a rapidly evolving market, selecting the right Limestone Crusher Machine is crucial. Consider the machine's maintenance needs and operational costs. A poorly chosen machine can increase expenses and reduce productivity. Therefore, understanding the key features of these machines is essential for making informed decisions in this competitive landscape.

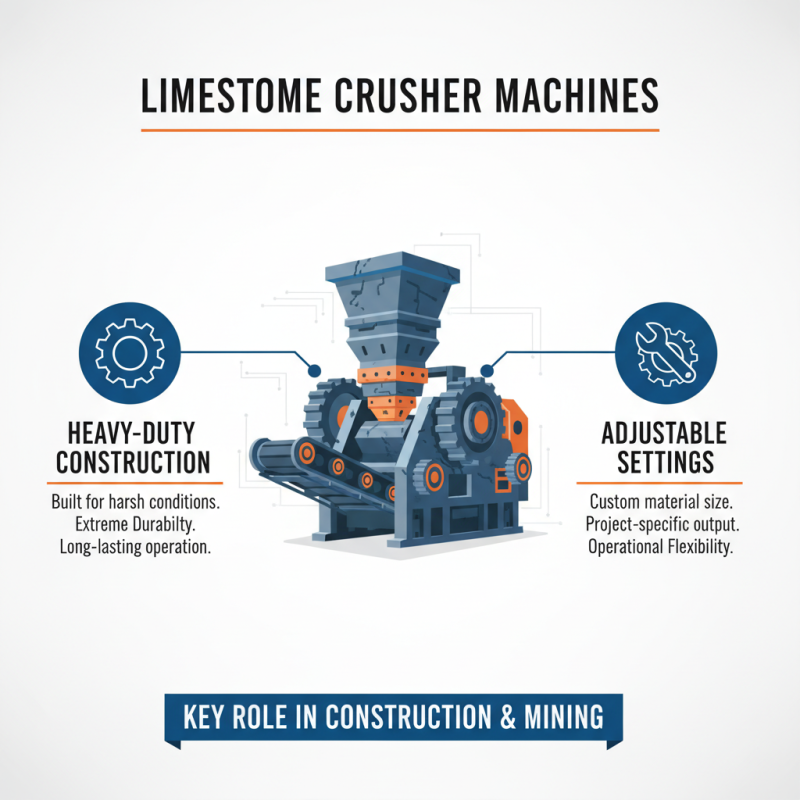

Limestone crusher machines play a crucial role in various industries, particularly in construction and mining. One important feature is their heavy-duty construction. These machines are designed to withstand harsh conditions and heavy loads. Durability is key, ensuring longevity in operation. Another key characteristic is their adjustable settings. Users can personalize the size of crushed materials to meet specific project needs. Flexibility in use is a significant benefit.

Efficiency is another prominent feature of limestone crushers. These machines are designed to reduce energy consumption while maximizing output. A well-optimized design can lead to lower operational costs. It’s also essential to consider maintenance requirements. Regular upkeep is necessary to prevent breakdowns and ensure smooth operation. Neglecting this aspect can lead to frustrating downtime.

Moreover, safety features are vital in limestone crushers. These machines often include protective guards and emergency stops. Operators should be trained to use these features effectively. Understanding the limitations of machines is crucial. Sometimes, operators may push for more than the machine can handle. This can lead to unexpected failures and safety risks. Awareness and caution should always be at the forefront.

In limestone processing, crushing efficiency plays a critical role. The efficiency of a crusher directly affects the overall productivity of the operation. According to industry reports, efficient crushing can increase mineral recovery rates by up to 20%. When the limestone is crushed accurately, it results in better quality material and reduced waste.

Many factors influence crushing efficiency. The type of crusher, its settings, and the material properties all contribute to effective processing. For instance, a well-designed impact crusher can reduce larger limestone pieces into smaller fragments consistently. Data shows that optimizing crusher settings can lead to a 15% increase in throughput. However, attention must be paid to maintenance; equipment that is not well maintained can cause bottlenecks and inefficiencies.

Despite advancements, many processing plants face challenges in achieving optimal performance. Underutilization of equipment remains common. Reports indicate that as much as 30% of the crushing capacity is often wasted due to improper feeding or poor operational practices. Regular training for operators and periodic equipment reviews can mitigate these issues, leading to improved crushing performance. In limestone processing, this not only enhances efficiency but also ensures sustainability in production.

When considering limestone crusher machines, durability and maintenance are crucial factors. These machines face wear and tear due to their heavy-duty operations. Choosing materials that withstand abrasive conditions is essential. Regular inspections can help identify problems early, minimizing downtime.

Maintenance routines should include checking wear parts and lubricating moving components. Neglecting these tasks can lead to costly repairs. Simple inspections can prevent larger issues. For instance, a worn-out conveyor belt may not seem critical but can cause significant efficiency drops.

Furthermore, operators must be trained to recognize warning signs. Strange noises or vibrations can signal impending failures. Taking these observations seriously can save resources. In the end, effective maintenance not only prolongs machine life but also ensures consistent performance within the crushing process.

Limestone crushing equipment has seen remarkable technological advancements. These machines now feature automated operations, reducing the need for manual labor. Users can expect improved efficiency with real-time monitoring systems. This helps detect issues early, lowering maintenance costs.

The addition of advanced materials enhances durability. Many machines now incorporate wear-resistant components. This leads to longer lifespan and reliability. However, some operators might struggle to adapt to these innovations. Training is essential. Without proper knowledge, one may face challenges in maximizing equipment potential. Embracing these changes can be difficult but necessary for optimization.

Innovative designs also focus on energy efficiency. Many machines consume less energy than their predecessors. This not only lowers operational costs but also reduces environmental impact. Still, some may overlook the importance of proper machine setup. Poor configuration can lead to suboptimal performance. Regular assessments and adjustments are crucial to harness technology effectively.

When choosing a limestone crusher machine, energy consumption is a major factor. Crushers vary significantly in their operational efficiency. A machine that consumes excess energy can inflate operational costs. This may not always reflect in pricing, but energy waste accumulates over time. High electricity bills can hinder profitability.

Operational costs consist of more than just energy usage. Maintenance expenses also play a role. Frequent breakdowns can lead to increased repair costs. The design of the machine impacts its reliability. Simple, easy-to-service designs can help minimize downtime. Alternatively, complex machinery may lead to unexpected failures.

Over time, analyzing these costs becomes critical. The relationship between energy consumption and operational efficiency can reveal hidden issues. You might realize that a seemingly efficient model isn't as cost-effective as it appears. Reflection on these points leads to informed decisions. Balancing initial investment and long-term costs is essential.

| Feature | Description | Energy Consumption (kWh/ton) | Operational Cost (USD/ton) |

|---|---|---|---|

| High Efficiency | Designed to maximize output per energy unit used. | 0.8 | 25 |

| Durability | Constructed from high-quality materials for longevity. | 0.9 | 30 |

| Low Maintenance | Requires minimal maintenance for operation. | 0.7 | 20 |

| Noise Reduction | Designed to minimize operational noise levels. | 1.0 | 28 |

| Versatile Design | Can handle various types of limestone and other materials. | 0.85 | 26 |

| Compact Size | Designed for easy transport and installation. | 0.75 | 22 |

| Safety Features | Equipped with safety mechanisms to protect operators. | 0.95 | 29 |

| Energy Recovery System | Recovers energy from operations to improve efficiency. | 0.6 | 24 |

| User-Friendly Controls | Easy-to-use controls for smoother operation. | 0.88 | 25 |

| Environmental Compliance | Complies with environmental regulations for emissions. | 0.77 | 23 |