As the mining industry continues to evolve, the quest for more efficient and effective solutions to extract valuable resources remains at the forefront of innovation. One critical component of this process is the Gold Ore Crusher, a vital tool that plays an essential role in maximizing ore processing efficiency and minimizing operational costs. In 2025, we anticipate groundbreaking advancements in Gold Ore Crusher technology that will not only enhance mineral recovery rates but also promote sustainable mining practices.

The innovations in Gold Ore Crusher designs are expected to reflect a deeper understanding of material processing dynamics, particularly in the realm of optimizing energy consumption and reducing environmental impact. By integrating cutting-edge technologies such as automation, predictive analytics, and advanced materials, mines worldwide can achieve significant improvements in their operational workflows. This article delves into the top innovations in Gold Ore Crushers expected to shape the future of mining, addressing the critical need for enhanced efficiency in resource extraction while aligning with global sustainability objectives.

As we explore the upcoming trends, it becomes evident that the future of mining lies in the synergy between technological advancements and environmentally responsible practices. The evolution of the Gold Ore Crusher is not merely about enhanced machinery but signifies a transformative shift towards a more responsible and efficient mining industry.

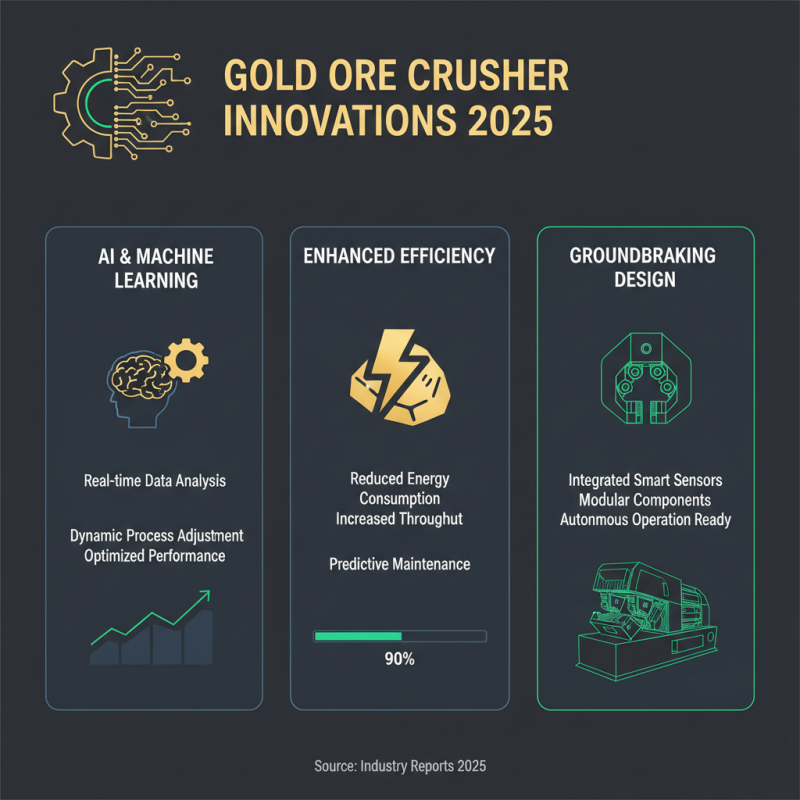

As the mining industry evolves, the technology behind gold ore crushers is advancing significantly, with 2025 expected to showcase groundbreaking innovations aimed at enhancing efficiency. One of the most notable trends is the integration of artificial intelligence and machine learning algorithms into crusher designs. These technologies facilitate real-time data analysis, enabling miners to adjust crushing processes dynamically, thereby optimizing performance and reducing energy consumption.

Additionally, sustainability is becoming a crucial factor in gold ore processing. New designs emphasize eco-friendly materials and energy-efficient operations. For instance, crushers that utilize renewable energy sources are on the rise, allowing for lower operational costs and a smaller carbon footprint.

Tips: When selecting a gold ore crusher, consider looking for models that offer automated monitoring systems. These systems can not only enhance operational efficiency but also improve safety by alerting operators to potential issues before they escalate. Keeping an eye on trends in sustainability can also guide your investment choices towards technologies that contribute positively to the environment while maximizing productivity.

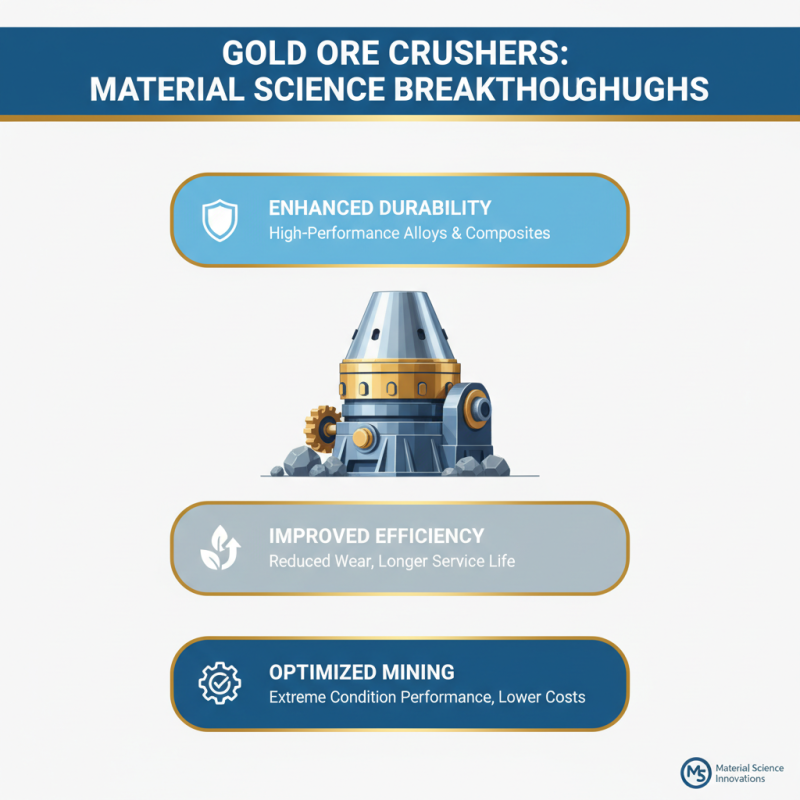

Advancements in material science are playing a crucial role in enhancing the durability and efficiency of gold ore crushers. The introduction of high-performance alloys and composite materials has significantly improved the wear resistance of critical components. These innovations ensure that crushers can withstand the harsh environments of mining operations, leading to longer service life and reduced maintenance costs. By utilizing advanced materials, manufacturers can create crushers that maintain peak performance even under extreme conditions, thus optimizing the mining process.

Tips for enhancing crusher performance include regular maintenance and monitoring of wear components. Keeping an eye on the condition of parts such as liners and hammers can prevent unexpected breakdowns and extend the lifespan of the equipment. Additionally, investing in predictive maintenance technologies can help identify potential issues before they escalate, allowing for timely interventions that save both time and money.

Furthermore, the integration of smart technology into crushers can also contribute to increased efficiency. By collecting and analyzing data on operational performance, miners can optimize their crushing processes based on real-time insight. This not only maximizes resource extraction but also minimizes energy consumption, resulting in a more sustainable mining operation. Embracing these advancements in material science and technology is essential for those looking to maintain a competitive edge in the evolving mining industry.

The integration of automation and artificial intelligence (AI) into gold ore crushing processes represents a significant leap forward for the mining industry. With the global gold mining market projected to reach approximately $200 billion by 2025, the efficiency of extraction and processing becomes ever more critical. According to a report by McKinsey & Company, implementing AI technologies can improve operational efficiency by 20-30%, which would have substantial implications for cost reduction and output maximization in gold mining operations.

Automated systems equipped with AI algorithms are now capable of optimizing crushing processes in real-time, improving the quality of ore output while minimizing waste. These systems can analyze data from various sources, including sensor inputs and historical performance metrics, enabling miners to predict equipment failures and optimize maintenance schedules. For instance, research from the International Journal of Mining Science and Technology indicates that mines using AI-driven predictive maintenance have seen a reduction in downtime by up to 50%—a critical benefit in an industry where time is directly linked to profitability.

Moreover, the introduction of robotics in the gold ore processing stage enhances precision in the crushing operation, ensuring that resource handling and processing are as efficient as possible. A study by the World Gold Council highlights that the adoption of automated crushing solutions not only speeds up the production rate but also significantly reduces the environmental impact by ensuring that energy is used efficiently. As automation technologies continue to evolve, we can expect the gold mining sector to experience transformative changes that drive sustainable practices while maximizing resource recovery.

This chart displays the advancements in automation and AI integration in gold ore crushing processes from 2020 to 2025, highlighting the percentage improvement in efficiency each year.

The environmental implications of gold ore crushing are becoming increasingly critical as mining operations strive for both efficiency and sustainability. According to a recent report from the International Council on Mining and Metals, mining contributes to approximately 10% of global greenhouse gas emissions, highlighting the need for innovative solutions that minimize environmental impact. Modern gold ore crushers are integrating advanced technology designed to reduce energy consumption, enhance resource recovery, and optimize processing efficiency. For instance, the use of energy-efficient motors and variable speed drives can lead to up to a 30% reduction in energy usage during the crushing process.

In addition to energy efficiency, contemporary gold ore crushing solutions are now incorporating waste management systems that address the environmental concerns associated with tailings and dust emissions. The World Gold Council suggests that effective dust suppression tactics can lessen airborne particulate matter by over 70%, significantly reducing health risks for workers and nearby communities. Furthermore, environmentally sustainable practices, such as the use of recycled materials in construction and water-efficient processes, are being adopted across the industry, paving the way for a greener approach to mining operations that balances economic viability with ecological stewardship.

In the realm of gold ore extraction, the choice of crusher design can significantly impact operational efficiency and cost-effectiveness. Traditional crushers, often characterized by their robust durability and straightforward engineering, have served the mining industry for decades. However, their limitations in speed, energy consumption, and wear-and-tear necessitate a closer look at innovative designs.

Emerging technologies in crusher design employ advanced materials and automated systems that not only enhance efficiency but also extend the lifespan of equipment.

Tips: When considering upgrades, evaluate the specific requirements of your mining operation. Assess the materials being processed and the production targets, as these factors can guide you in selecting a suitable innovative design. Additionally, look into energy-efficient models that could reduce ongoing operational costs.

Innovative designs, such as those incorporating smart technologies, offer real-time data analysis and predictive maintenance features that traditional crushers lack. This capability allows for immediate adjustments to be made in response to changing ore characteristics, optimizing throughput and minimizing downtime. Additionally, newer crushing mechanisms reduce environmental impacts by decreasing energy consumption and improving material recovery rates. Embracing these advancements not only modernizes operations but also aligns with the industry's increasing focus on sustainability.

Tips: Always keep abreast of the latest innovations in crusher technology, as the field evolves rapidly. Participating in industry seminars and trade shows can provide insights into which innovations are setting benchmarks in mining efficiency.