Slag crushers play a vital role in the metal recycling industry. According to Dr. Emily Chang, an expert in waste management technologies, "Effective slag processing can lead to significant cost savings." Understanding the different types of slag crushers is crucial for businesses operating in this field.

There are various slag crusher types, each designed for specific purposes. The impact of these machines on operational efficiency is undeniable. From jaw crushers to cone crushers, each type has unique features. However, many companies overlook the importance of selecting the right machinery. A mismatch can lead to inefficiencies and increased costs.

It's essential to explore the top 10 slag crusher types. This knowledge not only helps in making informed decisions but also impacts environmental sustainability. Embracing the right slag processing technology is key to optimizing resource recovery. The right choice matters, as it can transform waste into valuable materials.

Slag crushers are critical in recycling and managing industrial waste. They help break down slag, a byproduct of metal production. There are various types of slag crushers, each with unique features. Understanding each type is essential for optimizing efficiency in recycling processes.

Jaw crushers are often used for their versatility. They can crush large amounts of slag efficiently. Cone crushers offer a finer output and are ideal for tougher materials. Impact crushers utilize high-speed impacts to break down slag. This is effective for smaller, more brittle pieces.

Tip: Regular maintenance is crucial. Inspecting crusher parts can prevent unexpected breakdowns. Keep an eye on wear and tear. This saves costs in the long run.

Another type is the rotary crusher. It uses a rotating hammer system to crush slag. This can produce a uniform material size. Vibrating screens are also beneficial. They separate fine particles from larger debris.

Tip: Always analyze the material before choosing a crusher type. Not all crushers fit every situation. Some may not be efficient for specific types of slag. This misstep could lead to poor performance.

| Slag Crusher Type | Description | Key Features | Applications |

|---|---|---|---|

| Jaw Crusher | Utilizes compressive force to crush materials. | High durability, efficient grinding. | Metal recovery, size reduction. |

| Cone Crusher | Uses conical crushing head to break down materials. | Versatile, optimized for larger feed sizes. | Primary and secondary crushing. |

| Impact Crusher | Uses fast-moving bars to impact materials. | High reduction ratio, capable of handling large feed sizes. | Construction, demolition waste processing. |

| Hammer Mill | Uses hammers to crush materials. | Simple structure, easy maintenance. | Fine grinding, recycling. |

| Roll Crusher | Utilizes two rolls to compress and crush materials. | Uniform particle size, energy efficient. | Coal, glass, and mineral crushing. |

| Vertical Shaft Impact Crusher | Crushes materials using a high-speed rotating rotor. | Produce sand, cubic and high-quality aggregates. | Concrete and asphalt recycling. |

| Gyratory Crusher | Utilizes a gyrating cone within a chamber. | High capacity, suitable for large volumes. | Mining, mineral processing. |

| Mobile Crusher | A portable unit that can move to various locations. | Flexible operation, space-saving. | Construction sites, remote locations. |

| Scrap Metal Crusher | Designed to shred and recycle scrap metal. | Efficient metal recovery, space efficient. | Metal recycling, waste management. |

| Fluidized Bed Crusher | Uses air to fluidize the material, allowing for effective crushing. | Minimized dust, consistent particle size. | Mineral processing, chemical industry. |

Mechanical slag crushers play a vital role in various industries such as metallurgy and construction. These machines are designed to reduce the size of slag produced during metal smelting and other manufacturing processes. According to a recent industry report, the global slag recycling market is expected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This reflects an increasing need for efficient slag management.

The design of mechanical slag crushers often includes several key features. They utilize specialized blades and hoppers to handle heavy slag materials. Some models are equipped with advanced control systems, enhancing processing efficiency. However, not all machines meet industry standards. Many lack durability and can fail under tough conditions. This raises concerns about maintenance costs and operational reliability.

Functionality varies widely among different types of mechanical slag crushers. Some are designed for high-volume operations, while others focus on precision crushing. Industry reports indicate that poorly designed models can lead to significant downtime. This is a critical consideration for businesses aiming to maintain productivity levels. A well-designed slag crusher can effectively process tons of material, making it essential for companies to invest in the right technology.

This bar chart illustrates the various types of slag crushers commonly used in the industry along with their effectiveness in processing different types of materials. The data is represented in terms of their processing capacity (tons per hour).

Hydraulic slag crushers have gained prominence due to their efficiency and innovative design. They are widely used in the metal recycling industry. Reports indicate that the global slag recycling market is expected to grow at a CAGR of 7.5% from 2021 to 2028. This growth reflects the increasing need for sustainable practices.

One of the main advantages of hydraulic slag crushers is their ability to handle larger volumes. They can crush tough materials with minimal energy consumption. This helps maintain operational costs. Additionally, their hydraulic systems allow for precise control during the crushing process. However, maintenance can be challenging. Regular checks are required to avoid downtimes.

Applications of hydraulic slag crushers go beyond recycling. They are also used in construction and road building. The crushed slag can be used as a high-quality aggregate. This use helps in reducing landfill waste. Nevertheless, improper material handling can lead to contamination, which is a concern. The industry should focus on developing better training and better tools for operators. This can enhance overall performance and sustainability outcomes.

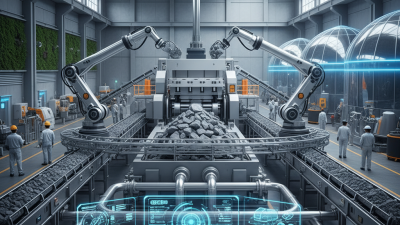

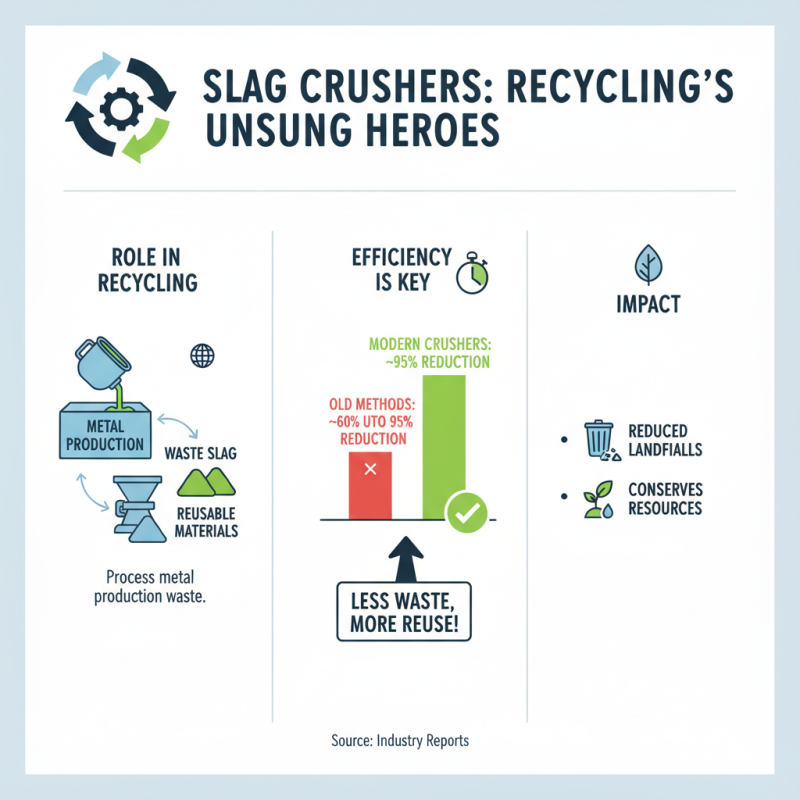

Slag crushers play a crucial role in recycling. They help process waste materials from metal production. Efficiency is key in selecting the right type. According to industry reports, the most effective slag crushers can achieve a reduction rate as high as 95%. This means less waste and more reuse potential.

Different types of slag crushers vary significantly in efficiency. Hammer crushers, for example, are effective for hard slag. However, their maintenance can become a burden. Jaw crushers may offer better durability but might not deliver the same level of efficiency in all cases. A comparative analysis reveals that cone crushers can strike a balance with their speed and power.

Energy consumption is another important factor. Some models consume up to 30% less energy than older designs. This leads to cost savings and a reduced carbon footprint. However, the initial investment in advanced technology can be daunting. Many companies hesitate, weighing benefits against costs. Finding the right crusher involves careful analysis and reflection on both current needs and future demands.

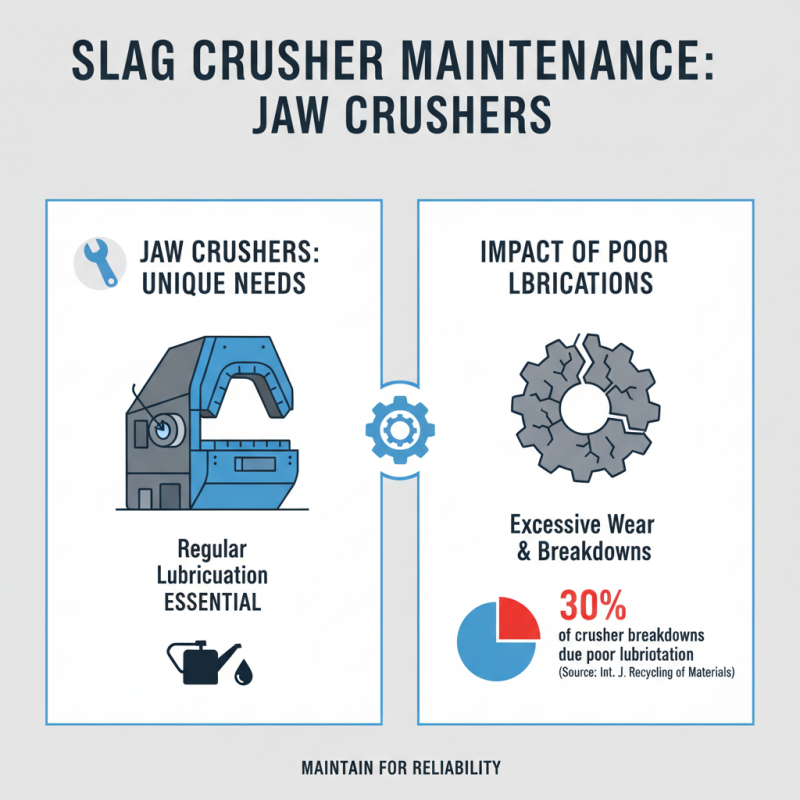

When it comes to maintaining different types of slag crushers, understanding their unique needs is crucial. For jaw crushers, regular lubrication is essential. Failing to lubricate properly can lead to excessive wear. According to a report by the International Journal of Recycling of Materials, nearly 30% of crusher breakdowns are due to poor lubrication practices.

For cone crushers, monitoring the wear of liners is vital. Worn liners can drastically affect performance and efficiency. Industry standards suggest replacing liners every 400 to 600 hours of operation. However, this can vary based on material characteristics and operational conditions. Conducting routine inspections can help identify wear before it becomes critical.

Impact crushers, known for their high production capacity, require regular checking of rotor balance. A poorly balanced rotor can lead to vibration issues and further mechanical failures. A study from the Journal of Construction and Building Materials indicates that improper rotor care can lead to a 15% decrease in productivity. These maintenance practices are not just about cost savings; they ensure the longevity and efficiency of equipment. However, many operators still overlook these details. That gap in awareness can lead to preventable downtime and excessive repair costs.