When it comes to construction, selecting the right equipment is crucial for success. One of the most essential pieces of machinery is the Stone Crusher, which plays a pivotal role in processing materials for a variety of projects. From road construction to the production of concrete, understanding the different types of stone crushers available can significantly impact efficiency and productivity. This article delves into the top 10 types of stone crushers, equipping you with the knowledge needed to make informed decisions tailored to your construction needs.

Stone crushers come in various shapes and sizes, each designed for specific applications and materials. Whether you’re dealing with large boulders or smaller aggregates, the right type of stone crusher can streamline your operations, enhance material quality, and ultimately ensure the durability of your projects. By examining the different types of stone crushers, including their unique features and operational advantages, you’ll be better prepared to select the most suitable equipment for your requirements. Understanding these key factors not only allows for optimal construction practices but also supports the longevity of the built environment.

When it comes to construction, the choice of stone crushers plays a pivotal role in ensuring the project runs smoothly and efficiently. Various types of stone crushers are tailored for specific applications, making it essential to understand their functions.

Jaw crushers, for instance, are widely used in the primary crushing stage for their ability to handle large rocks and break them down into manageable sizes. Their robust design and straightforward operation make them ideal for projects that require the processing of hard materials like granite and limestone.

Another notable type is the cone crusher, which excels in secondary and tertiary crushing stages. This crusher is particularly effective for producing finer aggregates while efficiently handling varying sizes of feed material.

Impact crushers are also vital in construction, as they utilize high-speed impact forces to crush stones, making them suitable for producing sand and gravel. Additionally, mobile crushers have gained popularity due to their versatility and ease of transport, allowing for on-site processing of materials. Understanding the diverse types and applications of stone crushers is crucial for selecting the right equipment for any construction project, ultimately enhancing productivity and ensuring quality outcomes.

Primary crushers are essential in the initial phase of the crushing process, where large stones are broken down into manageable sizes for further processing. Among the various types of primary crushers, jaw crushers stand out due to their efficiency and reliability. These machines use a pair of jaws, one fixed and one movable, to crush material by applying compressive force. This design allows them to handle a wide range of materials, from soft rocks to hard, abrasive substances, making them ideal for construction sites.

The features of jaw crushers make them particularly suited for various applications. They have a simple structure, which facilitates easy maintenance and repair. Their ability to easily adjust the size of the output material adds to their versatility, allowing operators to cater to specific project requirements. In addition, jaw crushers can operate on a continuous basis, ensuring high productivity levels, which is crucial in large-scale construction projects. With their robust design and powerful crushing capabilities, jaw crushers remain a popular choice for anyone looking to tackle heavy-duty stone crushing tasks efficiently.

Secondary crushers play a crucial role in the construction industry, particularly in the process of resizing and shaping materials to meet specific requirements. Among the various types of secondary crushers, cone and impact crushers are two of the most prevalent choices, each offering distinct operational advantages. Cone crushers are known for their ability to produce a finely crushed product with a uniform particle size. They operate by compressing the material between a fixed and a moving cone, which crushes the stones efficiently while maintaining a consistent output.

On the other hand, impact crushers utilize high-speed rotors equipped with wear-resistant hammers to collide with the aggregate material, breaking it apart through impact. This results in a different size distribution of the product, often favored for its ability to create more angular particles, which is essential for certain applications like asphalt and concrete production. Both types of secondary crushers are pivotal in transforming larger stones into manageable sizes that can be easily used in various construction projects. Understanding these crushing mechanisms helps builders choose the right equipment, optimizing material processing and enhancing the overall efficiency of construction operations.

This bar chart displays the effectiveness rating of various types of stone crushers used in construction. Ratings are based on performance metrics, with a scale from 1 to 10, where 10 represents the highest effectiveness in stone crushing tasks.

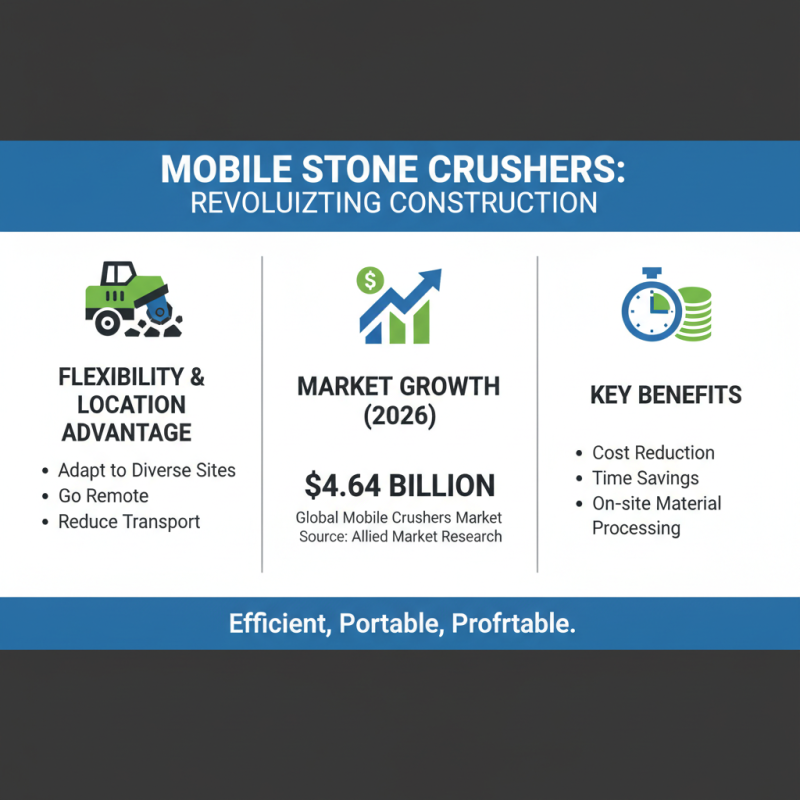

Mobile stone crushers have transformed the construction industry by providing superior flexibility and location advantages, catering to the diverse needs of construction sites. According to a market analysis report by Allied Market Research, the global mobile crushers market is projected to reach $4.64 billion by 2026, driven by the demand for efficient, portable solutions that can adapt to remote and varied landscapes. This trend highlights the increasing reliance on mobile units, as they eliminate the need for transporting materials to fixed crusher locations, thus reducing costs and time.

The inherent mobility of these crushers allows construction teams to operate closer to their extraction sites. This minimizes transportation distances and streamlines operations, which is particularly beneficial for projects situated in confined or challenging terrains. A report from the International Journal of Environmental Science and Technology emphasizes that mobile crushers not only enhance production efficiency but also contribute to decreased fuel consumption, leading to a smaller carbon footprint. By adapting to diverse operational environments, mobile stone crushers empower contractors to maintain productivity levels while fostering sustainability in construction practices.

When selecting the right type of stone crusher for your construction project, several key factors must be considered to ensure optimal performance and efficiency. Firstly, assess the material you will be processing. Different crushers are designed to handle various types of stones, such as granite, limestone, or sandstone. Understanding the characteristics of your material, including its hardness and size, can guide you toward the most suitable crushing solution.

Another critical factor is the desired output size and production capacity. Different projects may require various sizes of crushed stone, whether for aggregate in concrete or backfill material. Knowing your target specifications helps in choosing a crusher that not only meets the size requirements but also aligns with your production schedule. Additionally, consider the operating conditions and space constraints on the job site, as these can influence the type of crusher that will work best for your landscape and operational workflow.